Moving a CNC machine is no easy feat. Whether it’s being moved internally or externally, if it’s not relocated properly, issues can ensue, and your operations can be negatively impacted. The last thing you want is for your CNC machine to be damaged so you must be diligent in taking preventative measures. Your goal is to make sure your machine reaches its destination safely. In this guide, we will discuss with you the steps you should take to guarantee the safe relocation of your CNC machine.

Contact Sullivan Industrial Services for Any of Your CNC Machine Moving Needs in CT, MA, RI, or NY

Planning the CNC Machine Move

Evaluating Machine Size and Complexity

The first step you want to take is evaluating your CNC machine. You should carry out a detailed inspection of the machine to get an understanding of its current condition. Not only do you want to account for any wear and tear, but you also want to assess its geometry. A geometry report provides crucial information. It will indicate what geometry corrections need to be made. As for the wear and tear, it may be more cost effective to replace worn parts than pay for repairs.

Setting a Timeline for the Move

An essential beat in planning the CNC machine move is developing a timeline for it. A well-devised step-by-step plan is key to machine relocation. Having this detailed outline will keep downtime to a minimum.

Pre-Move Preparation

Securing the Right Moving Equipment

A CNC machine must be properly secured with the right moving equipment before being relocated. A CNC machine should be packaged in a box wrapped with corrugated cardboard. These cardboards provide plenty of cushion to the CNC machine during transportation. These cardboards also have the stability and strength to support the weight of a CNC machine. Crates are also essential for packing CNC machines. They have a self-supporting structure that can easily hold a CNC machine. Additionally, crates are available in a variety of materials such as wood, aluminum, steel, and plastic. Moreover, PE stretch film guarantees stability during transportation. This multilayer flexible polyethylene film will also protect the CNC machine from humidity.

Preparing the CNC Machines for Transport

Most CNC machines can be shipped intact, but some require disassembly depending on their mode of transportation. Once you figure out by what means you’ll be transporting your CNC machine, you can decide whether it needs to be disassembled. If it does, it is best to let a CNC technician handle this disassembling process as they have the knowledge to do it correctly. Having a professional take care of this can help you avoid employee injury and machine damage.

Logistics and Transportation

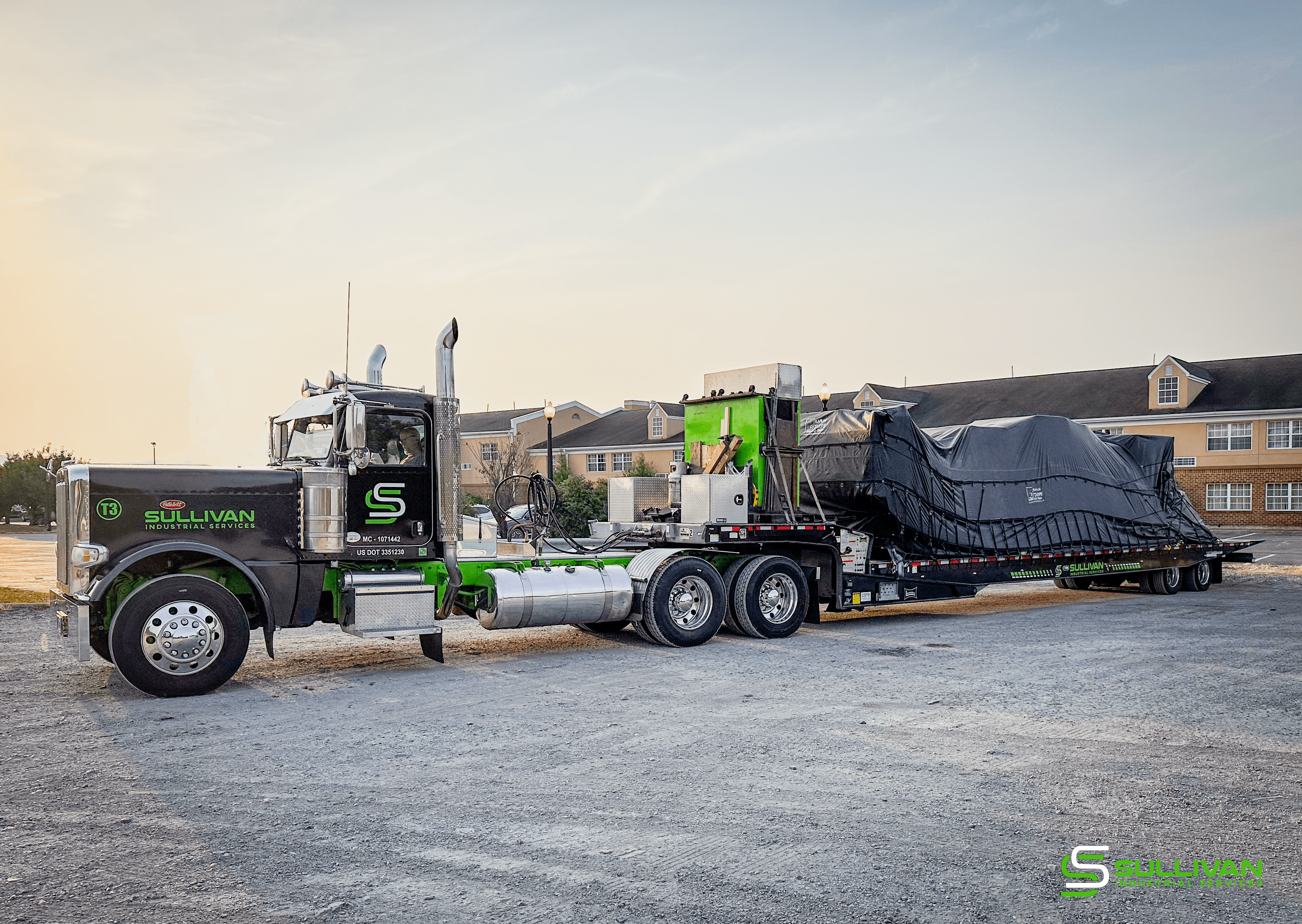

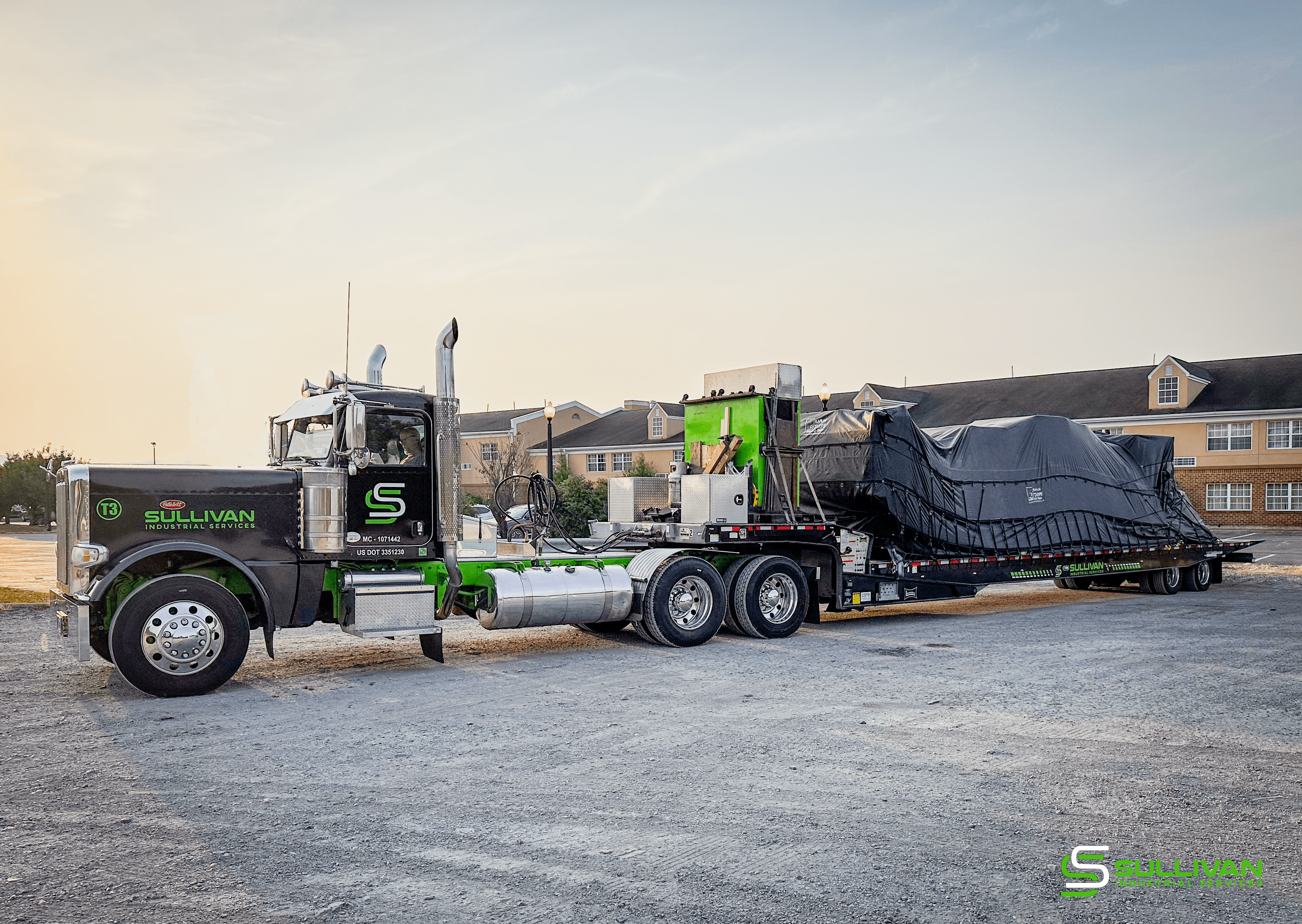

Selecting a Transportation Provider

When selecting a transportation provider, you want to choose a company that has the expertise and competency to get the job done right. Ask for referrals, check customer reviews, and see if they have the correct licenses. The company you select should have industry experience and know how to navigate any issues that may arise during transportation. There are major benefits of working with professionals. Most companies provide shipping services at an affordable rate. They have the necessary equipment to protect your CNC machine during transport. They can, also, get your machine ready and stabilized for relocation.

Coordinating Move Schedules

Your move schedule will depend on which transportation service option you use. Having a single dedicated truck for your CNC machine means that there is no additional freight. This allows you to dictate the pick-up and delivery time to meet your exact needs. With a truckload service, you can still customize your exact loading and delivery schedule, but other freight may be added to your cargo if it doesn’t conflict with your schedule. Lastly, a less than truckload service enables multiple shippers to share space on the truck. This is the most cost-effective method but there may be multiple transfers before your CNC machine arrives at its destination.

Heavy Hauling Guide

Sullivan Industrial Services goes beyond mere heavy haul transportation; we provide integrated services that ensure safe and timely freight transport locally, regionally, or globally.

CNC Machine Dismantling

Dismantling Process

It is recommended that your CNC machine be disassembled either by your own service engineers or better yet CNC technicians. Failure to disassemble your machine correctly can result in damage. Care and attention are essential during this process. These machines are made up of multiple components and these individual parts should be handled properly.

Organizing Parts and Components

Once you’ve dismantled your CNC machine, account for all its parts and components. Properly document each part and its condition. Having this record can help you keep track of the components. You can consult this record once the parts have arrived at the new site to ensure nothing is missing or damaged.

Packing and Loading CNC Machines

Protective Packing for Sensitive Components

We recommend using corrosion resistant packing to prevent the damage of any sensitive components during transport. You should also make sure you bolt your machine to a pallet or the bottom of a crate to ensure it doesn’t move around. You can also use industry standard ratchet straps for extra security. Shrink-wrap is also essential for security and padding as it can prevent your machine and its equipment from hitting any edges.

Safe Loading Techniques

CNC machines weigh substantially, so it’s imperative that they be loaded safely and properly. Before anything, you should remove any smaller parts or sensitive components that may be damaged during the transit process. It may be necessary and even best to use a forklift. Wood or rubber pads should be used between the forks and the CNC machine to create friction and decrease the likelihood of sliding. A cargo strap should also be wrapped around the CNC machine to prevent sliding.

Industrial Crating – A Complete Guide

Crating is a way in which products are packaged in order to be shipped and stored. Here, at Sullivan Industrial Services, we offer custom crating solutions for all of your storage and shipping needs.

Installation at the New Location

Preparing the New Site

Before your CNC machine arrives at its new destination, you should do your best to prepare the site for its arrival. This means more than just clearing the adequate space for it. It’s your responsibility to ensure that it can be readily installed and have the correct utility points.

Reassembling the CNC Machines

Expertise and accuracy are a must when it comes to reassembling your CNC machine at its new location. When reassembling it, ensure that it’s being done on a stable and level surface. You may want to refer to its original user manual for this part. A CNC technician can also be employed for this step as well.

Rigging & Machine Moving – A Complete Guide

In this guide, we give you a thorough and in-depth look into rigging and machine moving practices. We touch on types of rigging, rigging equipment, rigging techniques, workplace safety, and training.

Calibration and Testing Post-Move

Calibrating CNC Machines for Precision

As soon as you’re done reassembling your CNC machine, it should be calibrated for precision. In many industries, there are standards you must adhere to in relation to accuracy and precision. Calibrating the CNC machine ensures compliance with these regulations. Calibration can, in fact, do the following:

- Ensure the CNC machine is cutting to the correct dimensions.

- Identify any issues and prevent future costly breakdowns.

- Produce consistent and accurate results, critical for parts needing to be of certain dimensions.

- Guarantee the CNC machine operates at optimal speeds.

Performing Operational Tests

One of the last steps of the moving process is performing operational tests. Such assessments will confirm that your CNC machine is in working order and can function properly to the best of its ability.

Training and Documentation

Updating Operational Manuals

In certain situations, the operation of the CNC machine may change with the move. The new site may require an adjustment to the previous way of operating. In cases such as these, the operational manuals should be updated. In this way, employees can refer to them and operate the machine correctly.

Training Staff on Relocated Machines

Staff should be included in the relocation process as much as possible. They should be prepared for it and kept informed of any changes. Additionally, staff should be trained on the relocated CNC machine especially if there are updates on how it’s operated.

CNC Machine Moving: Conclusion

Yes, moving a CNC machine is not simple. However, if you come up with a comprehensive plan of action, it can be made all the easier. Take this process step by step and don’t hesitate to consult with professionals even. You’re already off to a great start by taking the time to read through this guide!

Contact Information for Specific Queries

For specific queries or more information, reach out to us at contact@sullivanindustrialservices.com or give us a call at 203-859-4238. We’re here to provide tailored solutions for all your machinery skating and rigging needs.

Recent Comments