Crating is a way in which products are packaged in order to be shipped and stored. In other words, a product is placed in a crate so it can remain secure and protected during transit. Crating is an essential service needed to make the supply chain effective. Many industries utilize crating as a way to safely ship their products, equipment, and machinery. Specifically, custom crating is a technique often used. Custom crates ensure that the crate itself fits the specific needs of whatever is being shipped. For example, if a product is sensitive to moisture, then a moisture prevention technique is used while building the crate. Additionally, the crate will be built to match the dimension specifications of the item.

Contact Sullivan Industrial Services for Any of Your Crating Needs in CT, MA, RI, or NY

Here, at Sullivan Industrial Services, we offer custom crating solutions for all of your storage and shipping needs. Our team specializes in creating custom domestic and global solutions to meet your packaging, skidding, and crating needs. Particularly in the Northeast, we work with clients in key areas across Connecticut, Massachusetts, Rhode Island, and New York. In this blog, we will provide you with all the information you need to know about crating. By the end of this guide, you’ll have a complete understanding of crating and how this service can be of use to your business.

Types of Crating Services

Industrial Crating

Machinery

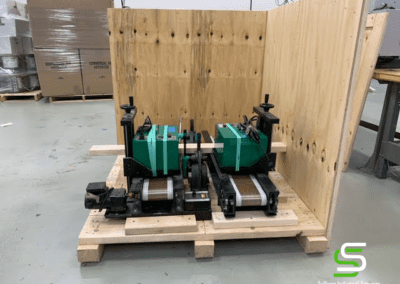

Typically, there is a large financial investment involved with machinery. This means it’s not enough to simply place these items on a truck and strap them down. It’s crucial that these valuable assets are crated and transported properly and carefully. Expert industrial movers will tell you that placing machinery in a crate helps to guarantee that said items will make it from their point of origin to their destination undamaged. Plenty of industries utilize crates to ship their machinery. For example, automotive manufacturers rely on custom crating to deliver million-part orders, heavy equipment axles, and dozens of rebuilt engines. Aerospace technologies also need the same uncompromising protection to keep their private and military-grade components safe. So, custom crating keeps machinery secure and reduces costs and risks across industries.

Heavy Equipment

When it comes to heavy equipment, it’s necessary to make sure that the crate they are in has plenty of cushioning. Without the correct type and amount of cushioning, heavy equipment can easily slide around the crate while being transported. As you can imagine, this is the last thing you would want to happen. Sliding means that parts of the equipment are going to smash into the sides of the crate. Adding cushioning is the best way to avoid this sort of disaster. There are different types of cushioning materials that you can choose from as well. We’ll delve into these materials a little later.

Another aspect to keep in mind regarding heavy equipment is the size of the load. The size of your equipment will determine whether crating is the best option for you. If you are unsure about this, be sure to seek advice from the professionals.

Commercial Crating

Furniture

Whether you’re an e-commerce retailer, an interior designer, or a resident transferring homes, moving furniture can be a hassle. However, with crating, shipping furniture can become more efficient and cost-effective. You can drastically reduce the likelihood of your furniture being damaged. Your furniture will arrive at their destination in the same condition they were sent in. Not only is the risk of damage reduced but you don’t have to worry about potentially having to spend money on replacing tarnished furniture. With proper crating, valuable, fragile, and even heavy furniture will be safe for long distances.

Electronics

Plenty of items in the electronics sectors need shipping including hi-tech equipment, telecom devices, sensitive electronics, server racks, and IT assets. Crating is essential because these items are often too sensitive, too big, too heavy, or too valuable to be handled any other way.

Electronic equipment is sensitive not just to impact, but to other threats such as static electricity, vibration, moisture, dust, and other contaminants. That’s why industries depend on crates. From data centers to Fortune 500 companies, crates are utilized for the safe and efficient shipping of electronics. Crating guarantees the smooth running of businesses. Moreover, electronics are given an optimal crating approach depending on their individual characteristics. Cushioning is more often than not used to prevent any harm being inflicted on electronics. Additionally, vapor barrier bags, desiccants, and plastic sheeting can be applied to electronics, furthering protecting them from outside elements.

Specialty Crating

Fine Arts and Antiques

There is an extensive shipping network when it comes to fine arts and antiques. Museums, auction houses, galleries, artists, and collectors all rely on crates to move delicate and valuable pieces around the world. Custom crating ensures that fragile, one-of-a-kind artworks are cushioned and transported under the right conditions. Art pieces will more than likely be given a full risk assessment prior to shipping. Afterwards, the appropriate crate can be built with the correct cushioning system. Crates are the sturdiest art packaging you can get and they are the best method for transporting across long distances.

Medical Equipment

Medical equipment, especially, needs to be handled with extreme care as this kind of equipment deals directly with people’s lives. All kinds of medical equipment is shipped including CT scanners, MRI machines, walking aids and wheelchairs, diagnostic equipment, X-ray devices, lasers, surgical equipment, etc. It is highly important that these items get to where they’re going undamaged and crates can ensure that they do. Crates can accommodate large and bulky medical devices as well as smaller, more fragile equipment. Some professionals even use computerized technology to match crates with the size of the equipment. Proper padding and insulation is also used to ensure that no items shift in transit.

Regional Services

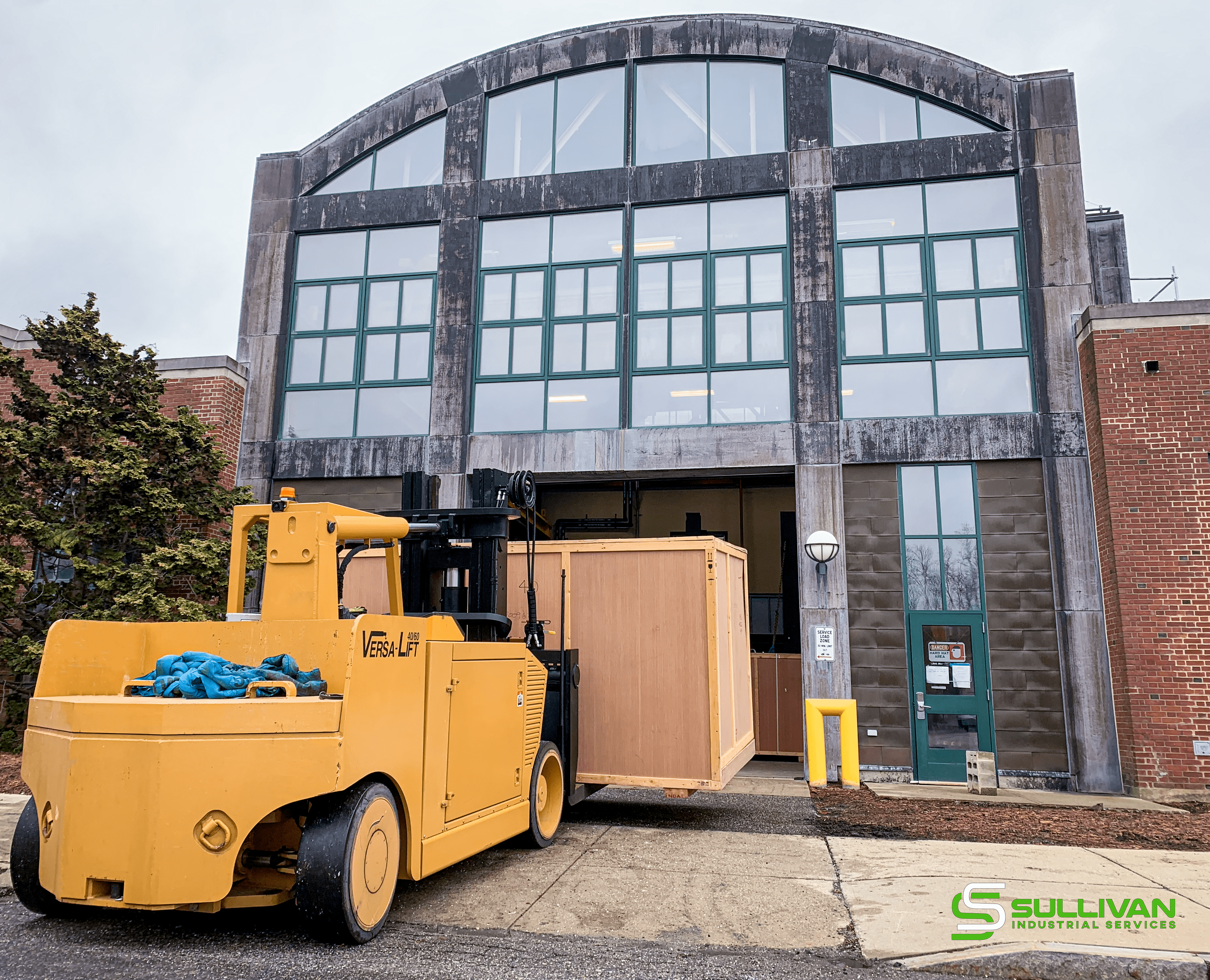

As we mentioned earlier, we offer our crating services in key areas throughout Connecticut, Massachusetts, Rhode Island, and New York. In fact, Sullivan Industrial Services has built crates for all sorts of equipment in these states. From small to large scale industrial equipment, our team is fully trained and equipped to handle it all. Our team is capable of constructing crates that can support and withstand equipment of substantial size. We also have the necessary equipment, such as forklifts and cranes, to efficiently handle these loads.

Safety Considerations in Crating

Personal Protective Equipment (PPE)

Personal protective equipment (PPE) is safety apparel that is worn to protect the body against hazards in the workplace. Wearing proper PPE minimizes the risk for serious injuries. That said, you absolutely should be wearing PPE throughout the crating process. Here’s a list of what you should be wearing:

- Safety Glasses: Safety glasses feature safety frames, safety lenses, and side shields to provide protection against dust and flying objects. Safety goggles provide coverage around the eyes and feature an adjustable head strap to ensure a secure fit with most head sizes.

- Hard Hats: This type of head PPE provides effective protection against falling objects and debris.

- Gloves: Work gloves protect your hands against cuts, heat, and liquids when handling hazardous materials or operating machinery. There are light-duty options for light box lifting, as well as heavy-duty gloves that are ideal for working with machinery.

- Steel Toe Shoes: Steel toe work shoes have a steel capping over the toe area to provide maximum protection against falling objects. They are ideal for workers who work with or around heavy machinery and objects, such as forklift operators. Steel toe shoes are the most common type of safety shoe used in a warehouse because of their high impact resistance.

- Ear Muffs: Safety ear muffs or earplugs will help reduce the noise of loud machinery and protect workers from eardrum damage or hearing loss in the future.

Crating Safety Standards

ISPM-15 Compliance

If you ever take a look at the wooden crate your equipment arrives in, you may notice an ISPM-15 label. ISPM-15 is an international measure that addresses issues related to the treatment of wood with a thickness greater than 6mm. This label certifies that the wood used to make the crates is free of insects, pests, and fungus. ISPM-15 requires crates to be made of wood that has been treated or fumigated to destroy insects and fungus. Once the wood pieces have been treated, they are stamped with ISPM-15, the company logo, and the date the treatment was carried out. The goal of ISPM-15 is to prevent the spread of disease and insects that could negatively affect plants or ecosystems.

Industry-Specific Regulations

Shipping is a complex process and it can be made even more complicated depending on the destination. A lot of industries not only ship items domestically but globally as well. When it comes to international shipping, there are plenty of regulations that you must abide by. Every country has its own requirements for the shipments that come across its borders. It’s extremely important to check the requirements specific to the country you’re shipping to in order to make sure that things go smoothly. Still, there are a few common requirements to consider when preparing to ship internationally.

As we touched on, if your crate is made of wood, it must have a ISPM-15 label. ISPM-15 affects all wood packaging materials, such as crates, requiring that it be debarked, heat treated, fumigated and stamped or branded with a mark of compliance. This measure is not just U.S. specific. Rather, the ISPM-15 stamp is a part of the International Plant Protection Convention, a treaty that has been signed by over 180 countries. You could face a hefty fee if you ship a wooden crate overseas without its proper label. Additionally, there are important documents that must be included when shipping crates overseas such as a bill of lading, a packing list, a commercial invoice, a certificate of origin, and a letter of credit.

Common Risks and Mitigations

Inadequate Padding

Most equipment requires some sort of padding or cushioning in its crate. Inadequate padding could lead to equipment damage during transportation. Without proper padding, equipment is left to slide around or face various impacts. This can be disastrous, especially for more fragile equipment. This is why padding is a necessary protective measure. By cutting the padding material to the exact dimensions of your items, you can prevent any gap that would allow the item to get loose or get damaged.

Weight Imbalance

Proper balance is crucial for safe and efficient crate shipping. Balancing crates means distributing them evenly on the ship, truck, or train, taking into account their weight, size, and type. Balance affects the stability, performance, and fuel consumption of the ship, truck, or train that carries the crate. Improper balance can cause accidents, damage, or delays. For example, an overloaded or unevenly distributed crate can topple over, break, or shift during transit, endangering the crew, cargo, and environment. Moreover, you have to follow the international and local rules that govern the weight and balance of crates, such as the SOLAS Convention and the VGM (Verified Gross Mass) requirement.

Environmental Factors

One hidden form of damage to equipment is the effects of environmental conditions—in particular, corrosion and other internal damage that can be caused to electronics like servers by high humidity levels, such as during ocean transport. However, precautions like moisture-barrier packaging, desiccants and humidity indicator cards can help ensure that sensitive items are protected.

Crating Materials and Technologies

Types of Wood and Metal Used

Pine

One of the most commonly used woods for wooden crates is pine. In addition to being both light and strong, pine is also relatively inexpensive. You can get a sturdy material without having to break the bank.

Plywood

One of the best advantages of plywood is that it comes in various levels of thickness. It, also, cannot split and offers great resistance to termites, mold, moisture, and heat. Baltic birch plywood is particularly desirable because of its durability and affordable price.

Aluminum

Of all metals, aluminum is the most common packaging material used. Crates made from aluminum tend to be made fast, have a lighter weight, have superior quality, and last longer. Additionally, aluminum is critical for the packaging industry because it is sustainable and cost-efficient.

Cushioning and Padding

Foam

Foam is an effective cushioning and vibration dampening medium especially for sensitive and/or fragile equipment. Foam can be used for blocking, bracing, and vibration protection in crates. Because foam is lightweight and relatively cheap to manufacture, it can protect a shipment during transit without adding substantial weight and cost.

Bubble Wrap

Bubble wrap is an excellent insulator against impacts and is exceedingly good at keeping items safe and secure during transit. Sometimes the transportation process includes rough handling or bumps in the road so companies protect their equipment with bubble wrap. Its bubbles of sealed air provide a flexible but durable cushion that forms a sturdy barrier against impact. When doubled or tripled up in layers and combined with a sturdy crate, it can protect equipment from even severe impacts. What’s great about bubble wrap is that it’s reusable. As long as most of the bubbles are intact, you’re good to use your bubble wrap, again and again, to protect your most valuable equipment in transit. This makes bubble wrap a much more eco-friendly option compared to most types of packaging.

Fastening Systems

Nails and Screws

The strength and stability of the crate mostly depends on the integrity of the fasteners. The nails and screws you use for the crate are extremely important. The following are the most common types of fasteners for crates:

- Ring Shank / Twist nails: Both ring shank and twist nails are similar in that they turn or twist as they drive into the wood, forming their own tread in the wood fibers.

- Scrail Fasteners: The Scrail brand of fasteners combines speed with holding strength. It’s half nail, half screw. They’re rapidly driven into wood using common nail guns.

Strapping

Strapping is the most common means of unitization and bundling in the packaging industry. There are several types of materials that strapping can be made from. Steel is the oldest, strongest, and highest tensile strength strapping available. It is available in a variety of widths and thicknesses, as well as variations in the grade of steel. Steel is used for heavy duty holding where high strength and minimal stretch are needed, as well as when the product may be sharp or hot. Polypropylene and polyester strapping are the main types of plastic strapping. Polypropylene strapping is an economical material designed for light to medium. It is available in various widths and thicknesses. Polyester strapping is the most rigid option, offering the strongest plastic strapping, and is used as a viable alternative to steel in many industries. Polyester provides excellent retained tension on rigid loads and its high-performing recovery properties help a load absorb impact without strap breakage.

Moreover, there are multiple applications and purposes for strapping such as:

- Bundling items together for handling and shipping

- Attaching items to pallets, skids, and crates

- Reinforcing wooden boxes, crates, and corrugated boxes

- Attaching items to flatcars, flatbed tractor trailers, etc.

- Closing shipping crates

- Load securing items within intermodal containers, boxcars, and tractor trailers.

Heat-Shrinking Wrapping Technologies

Heat shrink wrap can be utilized for equipment that need both short-term and long-term storage. This wrapping technique ensures that items are protected against the elements. Heat shrink wrapping can be used for damage abatement, product containment, construction site weatherization and protection, and economical asset protection. If you want to preserve and protect an item, it pays to shrink wrap it.

Crating Techniques and Best Practices

Dimensioning and Measuring Techniques

Measuring the dimensions of a crate is somewhat straightforward. Taking measurements is crucial especially for your equipment’s safety and in the case of custom crating. Accurately measuring a crate does require close attention to detail. Crate dimensions are a critical part of any package as they significantly impact what materials are needed, the cost of production, and shipping and warehousing costs. Think of it this way; minimal room for movement in a crate means minimal room for damage and a reduction of your overall costs.

You must measure the length, width, and depth of the inside of your crate, as this is the industry standard order of dimensions.

- Length: The longest side when looking at the top of the crate.

- Width: The shorter side when looking at the top of the crate.

- Depth: The side perpendicular to the length and width.

The next step after taking these measurements is to calculate the volume of the crate. Knowing the volume will help you determine how well your equipment will fit inside the package and will give you a better understanding for your shipping, warehousing and distribution processes. To calculate the volume, use the following formula:

- Length x Width x Depth = Volume

Padding and Cushioning Strategies

There are several types of cushioning that provide an extra layer of protection for equipment that will be transported. Specialized cushioning minimizes vibration and ensures items don’t come into contact with the walls of their crate. Customized cushioning is also used for that purpose. For light and delicate components, a polyurethane foam is often utilized.

For heavier assets, a polyethylene foam is typically the solution. Other materials like felt can also be used to help protect the surface finish of the units being crated. Furthermore, anti-static material is particularly used for electronics. Electrostatic discharge can damage sensitive electronics. However, anti-static packaging materials such as anti-static stretch wrap, bubble wrap, and foam can be used to avoid that problem.

Load Weight Distribution

The weight of your equipment should be evenly distributed over the entire area of the container’s floor. If the weight of your item is densely concentrated, distribute its weight with padding. You may not exceed the maximum mass/weight capacity of a crate with the equipment you load into it.

Environmental Protection

Not only must you protect your equipment from the bumps and hurdles of transportation but you must consider environmental protection as well. For example, water vapor damage is a common threat equipment faces. That’s why it’s so important that you invest in moisture-barrier crating materials. Anything being shipped by boat or plane should be protected from moisture. A small amount of saltwater in an ocean container can do a vast amount of damage and the rapid changes in pressure and temperature that occur during flight introduce moisture risk, as well. Moisture protection is especially vital for electronics and any equipment with unfinished machine parts. Time is moisture’s best friend. If a crate with a small amount of moisture is allowed to sit for any significant length of time, that moisture will have ample opportunity to corrode and warp delicate machinery.

Here are some materials you can use to combat moisture:

- Desiccant: Desiccant works like a sponge, soaking up any water vapor from the environment. There are many varieties of desiccant, and each has an upper limit in terms of how much water vapor it can absorb.

- Volatile Corrosion Inhibitors (VCI): VCIs emit chemicals that battle the corrosive minerals in water. There are three types of VCIs: paper, poly, and emitters.

- Vapor Barrier Bags: A vapor barrier is basically industrial-sized Saran Wrap. The vapor barrier bag is designed to prevent environmental moisture from entering the space surrounding your equipment.

- Nitrogen Purging: For especially sensitive shipments, the moisture-rich air surrounding your equipment can be replaced with nitrogen, which is a safe, inert gas.

- Humidity Monitor: A re-usable gauge visible through a window installed in the crate, the humidity monitor serves as an early warning system. If it edges into the danger zone, the crate can be opened and the desiccant and/or VCI can be replaced to mitigate moisture damage until the crate can be fully unpacked. The humidity monitor should be visible through the crate window.

Training and Certification

Available Courses in Specific Regions

If you live in the Northeast and are interested in learning how to build crates then you may want to check out the Rochester Institute of Technology in New York. This school offers education in packing including shock and vibration testing, dangerous goods training and customs processing as well as all other international concerns. If you want to become a professional in crating then this is a good place to start.

Importance of Certification

To pass crating certification exams and earn certification, comprehensive training is required to gain adequate technical knowledge and hands-on skills. Earning a certification is really proof that an individual has the ability to perform their jobs more safely and efficiently.

How to Choose a Training Provider

When it comes to choosing a training provider, you want to choose a provider that offers impactful and consistent training that will nurture your progress. There are online opportunities as well as in-person training. Both forms have their merits. Online troubleshooting simulations provide trainees with the opportunity to practice newly taught skills immediately, improving long-term knowledge retention and skill mastery. Practicing in a virtual environment reduces the risk of equipment damage, injury, or production downtime during training. On the other hand, in-person training will give you hands-on experience so you know exactly what you’re getting into. Some training providers even offer a multi-training format. In-person and virtual training combines the knowledge retention gains of live training with the ability for workers to learn in their own environment, resulting in the best skills gain for your workforce.

Future Trends and Technologies in Training

Automation in Crating

Crating automation is the process of crating products without the need for manual human intervention. Over the years, automated crating systems have transitioned from singular machines that automate one step in the crating process to now integrating all steps into the entire cratinging process. Automatic crating machines come in a variety of forms, but all fall under the automatic or semi-automatic category. One example of an automatic crating machine is the G3 Automation® crating and palletizing cell. The G3 Automation® crating and palletizing cell integrates diverse operations into high-performance automation. The automation cell receives the products by a conveyor belt, inserting them into the boxes, where they go through a continuous process of assembly and sealing, to be delivered to a palletizing robot, responsible for transferring them to a pallet.

Sustainable Materials

Crating can be an eco-friendly process. Crates can be made out of sustainable materials and still be just as sturdy and efficient. Such materials include:

- Reclaimed or Recycled Wood: Reclaimed or recycled wood has a much lower environmental impact than harvesting new timber.

- Bamboo: Bamboo is a type of plant that grows back quickly within only 3-5 years. It is 100% biodegradable, antibacterial and eco-friendly if not chemically processed. Bamboo makes a perfect choice in the construction world because it is incredibly strong as well.

- Plant-Based Polyurethane Rigid Foam: Plant-based rigid foam is often used as insulation and furniture material. It’s made from hemp, kelp and bamboo, which makes it resilient to moisture and heat. It even has better insulation and thermal resistance than fiberglass. It excels at protecting against mold and pests.

- Mycelium: Mycelium is the vegetative part of a fungus fiber that runs underneath the ground. Once it’s dried, it can be used as a building material. It has customisable material properties and can replace foams, timber or plastics for applications. Mycelium has superior strength, is eco-friendly, and is resistant to water, mold and fire.

Virtual Reality and Augmented Reality in Training and Visualization

Immersive technologies such as virtual and augmented reality can offer businesses the opportunity to revolutionize the design and production of products, as well as adapting the way employees work and learn. Quite simply, VR and AR can help businesses to save time and money by streamlining workplace practices and producing improved products faster and more efficiently. Additionally VR and AR may hold the key to training employees effectively and at speed. VR based training offers employees a space to undertake practical, hands-on and realistic experiences, but in a risk free environment. Augmented reality (AR), a technology that blends real and digital worlds via devices such as the Microsoft Hololens 2, as well as more widely available devices such as tablets and smartphones can provide a hands-on learning experience to support real life, on-the-job training.

Crating Services Near Me in Connecticut

When you hire Sullivan Industrial Services for your crating project, you can expect you are hiring the best crating team in the area. Our consistent focus on safety and efficiency is always at the forefront of each and every industrial crating project. You can trust that the Sullivan Industrial Services team will ensure a safe and secure relocation of your valuable industrial machinery. From small forklift picks to large crane projects our team has the equipment to get the job done.

Sullivan Industrial Services is warehoused in Milford, CT with a second location in Bloomfield, CT, and serves small and large businesses throughout Connecticut including but not limited to:

- Shelton

- Stamford

- Bridgeport

- Bethany

- Danbury

- Norwalk

- New Haven

- East Haven

- Trumbull

- Greenwich

- New Fairfield

- Newtown

- Bethel

- Hamden

- Waterbury

- Meriden

- Naugatuck

- Woodbridge

- Hartford

- New London

- New Britain

These are just some of the towns that Sullivan Industrial Services offers our assistance in, so don’t worry if you don’t see your town listed here. Our services extend throughout all of Connecticut.

Hire the Right Crating Company

In this guide, we have given you a thorough and in-depth look into crating practices. We’ve touched on types of crating materials, crating techniques, workplace safety, and training. The information we’ve discussed is not just for your knowledge, but in sharing this guide, we hope to encourage proper crating practices. Crating is incredibly important across industries and must be done with care. That’s a firm belief we hold here at Sullivan Industrial Services. We take our crating seriously and we ensure that we engage in proper crating operations. If you have any questions or would like to inquire about our crating services in CT, MA, RI, and NY, please don’t hesitate to reach out!

Recent Comments