Table of Contents

Understanding the Process of Decommissioning Machinery

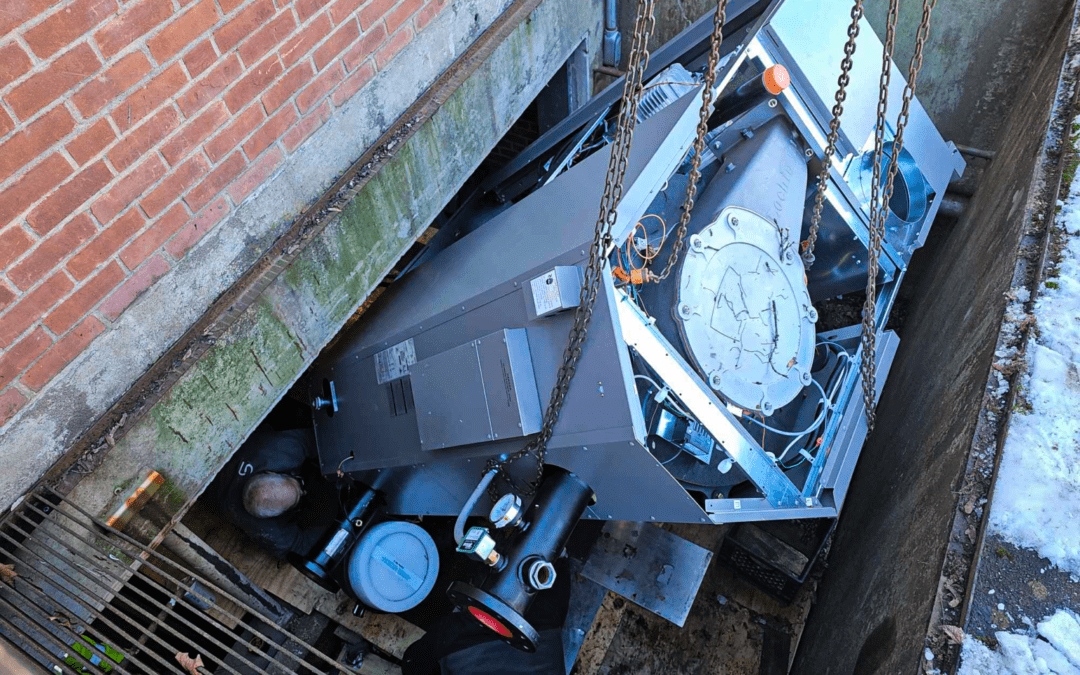

At Sullivan Industrial Services, we have extensive experience in safely and efficiently decommissioning machinery across various industries. Decommissioning involves the permanent removal of a machine from its operational state. This process can be complex, often requiring rigging or crating as well as an approach to ensure safety, environmental responsibility, and cost-effectiveness. This guide will provide a comprehensive overview of the decommissioning process, from initial planning to final disposal or reuse.

Contact Sullivan Industrial Services for Any of Your Machinery Decommissioning Needs in CT, MA, RI, or NY

Reasons for Decommissioning and Assessing Machinery

Several factors can prompt a company to decommission a machine. Here at Sullivan Industrial Services, we consider these key reasons when evaluating machinery for decommissioning:

- Age and Condition: As machinery ages, it becomes more prone to breakdowns and may not operate as efficiently.

- Repair Costs vs. Replacement Costs: Sometimes, repairing a machine is simply not cost-effective compared to purchasing a newer, more efficient model.

- Availability of Spare Parts: If spare parts become difficult or impossible to find, continued operation becomes impractical.

- Obsolescence of Technology: Newer technologies may offer significant improvements in efficiency, safety, or production capabilities, making older machinery obsolete.

- Environmental Impact: The continued operation of some machinery may have negative environmental consequences, such as high energy consumption or hazardous waste production.

A thorough assessment is crucial before decommissioning any machinery. Sullivan Industrial Services considers all of these factors to determine the most appropriate course of action.

Options for Decommissioned Machinery

Once a machine has reached the end of its operational life and been decommissioned, the question arises: what to do with it? Sullivan Industrial Services understands that you may have various options in mind, and we can help you navigate the best course of action for your specific needs. Here’s an overview of the most common choices for decommissioned machinery:

Selling and Auctioning

- Online marketplaces or auction houses specializing in used machinery

- Condition reports and fair market value considerations

- Disassembly and transportation logistics for buyers

Recycling and Scrapping

- Identification of recyclable materials (metals, plastics, etc.)

- Partnering with certified recycling facilities

- Data wiping and security measures for electronic components

Donating or Repurposing

- Identifying charities or schools that can benefit from the equipment

- Modifications needed for repurposing the machinery

- Liability considerations when donating

Plant Relocation and Reorganization Guide

For one reason or another, you may find it more beneficial to relocate your plant. An endeavor easier said than done. There is a lot that goes into relocating and reorganizing a plant or shop. You have to consider your employees, equipment, budget, productivity, etc.

Legal and Environmental Considerations

Decommissioning machinery involves more than just disassembly and disposal. Legal and environmental regulations play a critical role throughout the process. As a trusted partner, Sullivan Industrial Services prioritizes both compliance and sustainability in every decommissioning project we undertake.

Compliance with Regulations

- Local, state, and federal regulations regarding hazardous materials disposal, worker safety, and environmental protection.

Environmental Impact and Sustainability

- You are minimizing waste generation through recycling and responsible disposal.

- We are considering the energy efficiency and environmental impact of replacement equipment.

Best Practices in Decommissioning Machinery

Decommissioning machinery safely, efficiently, and responsibly requires a well-defined approach. Sullivan Industrial Services has extensive experience in this field and can guide you through the entire process. Here, we’ll delve into some of the best practices to ensure a successful decommissioning project:

Choosing the Right Service Provider

- Experience with similar machinery types

- Safety record and certifications

- Insurance coverage and liability protection

- Waste disposal and recycling capabilities

Ensuring Safe and Efficient Decommissioning

- Lockout/tagout procedures to prevent accidental activation

- Proper handling of hazardous materials (oils, coolants)

- Use of appropriate tools and equipment for disassembly

- Clear communication and project management

Common Machine Types Handled by Sullivan Industrial Services

Sullivan Industrial Services specializes in handling machinery commonly found in industrial and manufacturing settings. Our expertise extends to various types of equipment being rigged or crated, ensuring a smooth and efficient decommissioning process regardless of your needs. Here’s a breakdown of some of the most common machinery categories Sullivan can handle:

- Construction Equipment: Cranes (mobile and overhead), forklifts, bulldozers, excavators, dump trucks, loaders, backhoes, graders, pavers, concrete mixers, and other specialized construction vehicles.

- Manufacturing Equipment: Machine tools (lathes, mills, drills, presses, shears), welding equipment, assembly lines, industrial robots, CNC machines, and other production machinery.

- Process Equipment: Printing presses, bottling lines, food processing equipment, chemical processing equipment, oil and gas equipment, and similar industrial machinery.

- Power Generation Equipment: Turbines, generators, transformers, boilers, cooling towers, and related power plant equipment.

- Medical Equipment: MRI machines, CT scanners, X-ray machines, and other diagnostic and treatment equipment.

- Facility Equipment: Heating, ventilation, and air conditioning (HVAC) systems, elevators, escalators, and generators.

Manufacturing and Processing Machinery

In addition to construction equipment, Sullivan Industrial Services has experience with a variety of manufacturing and processing machinery, including:

- CNC Machines: Computer Numerical Control (CNC) machines are crucial in modern manufacturing. Sullivan Industrial Services understands the intricacies of decommissioning and maintaining CNC equipment.

- Conveyors: Whether it’s belt conveyors, roller conveyors, or screw conveyors, we have the expertise to handle decommissioning and servicing these material handling systems.

- Packaging Equipment: Sullivan Industrial Services has experience with various packaging equipment used in manufacturing operations, from filling machines to labeling machines.

Guide to Moving CNC Machines

Moving a CNC machine is no easy feat. Whether it’s being moved internally or externally, if it’s not relocated properly, issues can ensue, and your operations can be negatively impacted. The last thing you want is for your CNC machine to be damaged so you must be diligent in taking preventative measures.

Conclusion

Decommissioning machinery can be complex, but with careful planning and the right partner, it can be completed safely, efficiently, and responsibly. Sullivan Industrial Services offers extensive experience and expertise in handling all aspects of the decommissioning process, from initial planning and assessment to final disposal or reuse.

We understand the importance of adhering to legal and environmental regulations, prioritizing worker safety, and minimizing environmental impact. Our team of certified professionals has the knowledge and tools to handle various machinery types commonly found in industrial and manufacturing settings.

Recent Comments