Table of Contents

Introduction

Relocating a plant or factory is a complex process that requires strategic planning, logistical expertise, and a trusted partner to ensure a smooth transition. For businesses in the Northeast considering a move to Tennessee, Sullivan Industrial Services offers end-to-end solutions, from equipment rigging and transportation to installation and setup. Our experienced team has successfully relocated numerous manufacturing facilities, helping companies capitalize on Tennessee’s business-friendly environment, lower operational costs, and growing industrial sector.

Do you have a question about moving your business to TN? Contact Sullivan Industrial Services to Get Started!

Benefits of Relocating to Tennessee

Tennessee is a prime destination for manufacturers looking to reduce costs and improve efficiency. Companies moving from the Northeast can expect to benefit from:

Lower Taxes

Tennessee boasts no state income tax and lower corporate tax rates than many Northeast states, providing significant long-term savings for businesses.

Business-Friendly Regulations

Tennessee’s fewer regulatory hurdles and pro-business government make it easier for manufacturers to set up and operate efficiently.

Strategic Location

Located centrally in the U.S., Tennessee offers easy access to major markets via a well-developed highway system and rail networks near significant ports.

Skilled Workforce

The state has invested in workforce development programs, ensuring a steady supply of skilled labor across various manufacturing sectors.

Lower Cost of Living

Employees relocating from the Northeast will benefit from Tennessee’s affordable housing and overall lower cost of living, which can improve employee retention and satisfaction.

Case Studies – Businesses We Have Moved to Tennessee

At Sullivan Industrial Services, we specialize in handling complex industrial relocations. One notable project involved assisting a well-known firearm manufacturer move its operations from Massachusetts to Tennessee. Our team provided full-service relocation solutions, ensuring the company’s equipment and infrastructure were safely transported and reinstalled precisely. While details of the move will be provided later, this case highlights our ability to manage high-profile industrial relocations efficiently.

Planning Your Relocation

A successful relocation starts with a well-thought-out plan. Sullivan Industrial Services follows a structured approach to ensure every aspect of the move is handled professionally:

- Site Assessment & Planning: We conduct an in-depth analysis of your current and future facilities to create a comprehensive relocation strategy.

- Disassembly & Packing – Our team carefully dismantles machinery, packs components securely, and prepares everything for transport.

- Transportation & Logistics—We utilize specialized equipment and experienced drivers to safely transport your assets to their new location.

- Installation & Setup – We handle equipment placement, assembly, and final calibration to ensure operational efficiency upon arrival.

Post-Relocation Support – We provide troubleshooting, equipment testing, and ongoing support to ensure a seamless transition.

Ensuring Minimal Downtime During Relocation

One of the biggest concerns for manufacturers is minimizing operational disruption during a move. Sullivan Industrial Services takes proactive steps to reduce downtime, including:

Pre-Move Coordination

Developing a detailed relocation schedule to align with production needs.

Phased Relocation Strategy

Moving critical equipment in stages to allow partial operations to continue.

Rapid Installation & Testing

Deploying expert teams to expedite setup and ensure equipment is production-ready as quickly as possible.

Backup Plans

Addressing potential challenges in advance to prevent unexpected delays.

Equipment & Machinery Handling Expertise

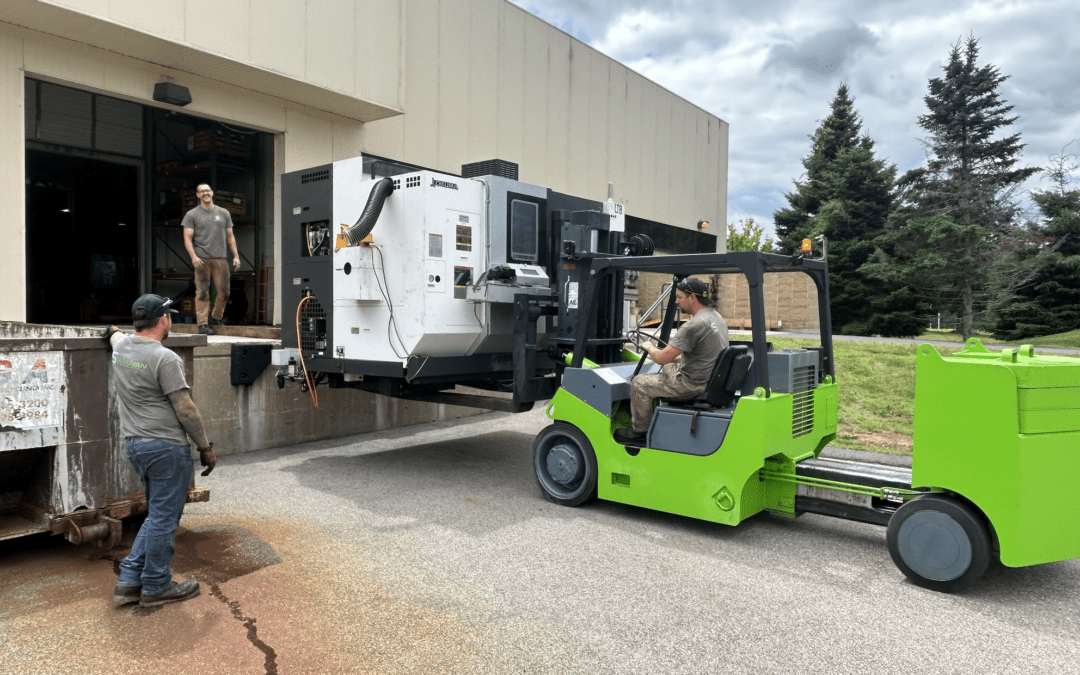

Relocating heavy industrial equipment requires precision, expertise, and the right tools. Our team is skilled in handling a wide range of machinery, including:

- CNC machines

- Injection molding equipment

- Printing presses

- Large-scale manufacturing lines

- Custom-built industrial machinery

With specialized rigging, crating, heavy hauling, and safety-focused procedures, we ensure every piece of equipment arrives intact and is installed correctly.

Plant Relocation and Reorganization Guide

In this guide, we’ll share with you all the essential aspects to consider when relocating or reorganizing your plant or factory.

Regulatory Compliance & Permits

Every state has its regulations governing industrial relocations. Sullivan Industrial Services assists clients with:

- Permitting for oversized loads and heavy equipment transport.

- Compliance with environmental and safety regulations.

- Coordination with state and local agencies to streamline approvals.

Why Choose Sullivan Industrial Services?

With years of experience in factory relocations, Sullivan Industrial Services has built a reputation for reliability and excellence. Our team offers:

- Comprehensive Relocation Solutions – We handle every aspect of your move, from planning to installation.

- Experienced Professionals – Our technicians and logistics experts ensure precision and efficiency.

- Customized Approach – Tailored relocation plans designed to meet your specific needs.

- Commitment to Safety – Adhering to industry best practices and standards at every stage.

Moving Machines & Equipment Across CT & the North East

Sullivan Industrial Services is warehoused in Milford, CT with a second location in Bloomfield, CT, and serves small and large businesses throughout Connecticut and the North East including but not limited to:

Get Started on Your Tennessee Relocation Today

If you’re considering moving your plant or factory from the Northeast to Tennessee, trust Sullivan Industrial Services to manage the process seamlessly. Contact us today for a consultation, and let us help you plan a successful transition to your new facility.

Recent Comments