Table of Contents

Welcome to Sullivan Industrial Services, your go-to partner for rigging & machine-skating projects. Our skilled riggers specialize in assembling new equipment and safely dismantling decommissioned machinery. Trust our experienced rigging team for seamless plant relocations and precise skating, ensuring a hassle-free experience. In this blog, we will focus on machinery skating, everything from what it is to why it’s important.

Contact Sullivan Industrial Services for Any of Your Machinery Skating Needs in CT, MA, RI, or NY

Introduction to Machinery Skating

At Sullivan Industrial Services, we excel in the art of machinery skating—a meticulous process that consists of moving heavy equipment with finesse. Our skilled professionals use low-friction skates and a strategic approach to seamlessly roll all kinds of machinery into position. This technique guarantees safe relocation, preserving the integrity and longevity of your equipment. It’s the essence of any top-notch rigging service.

Importance in Industrial and Commercial Relocations

- Efficiency Boost: Picture your machinery swiftly transitioning, minimizing or even eliminating shift downtime.

- Preservation of Equipment: We delicately move your assets, safeguarding their structural integrity.

- Cost-Effective: Our method saves you from potential repair expenses by ensuring a damage free relocation.

- Versatility: From manufacturing facilities to corporate offices, we adapt, handling diverse machinery and items with precision.

- Safety Assurance: Trust in our professionals to execute skating maneuvers with the utmost care.

- Time-Saving: Streamlining the process, we ensure your project stays on schedule.

- Expert Handling: Our skilled riggers bring expertise to every move, ensuring flawless transitions.

The Machinery Skating Process

Machinery skating plays a crucial role in the smooth relocation of heavy equipment and maintaining operational flow in industrial enviroments. We take pride in a method that prioritizes precision and care, ensuring the safe handling of your machinery. This not only preserves equipment life but also enhances efficiency, making it an essential element in industrial and commercial plant relocations.

Planning and Assessment for Skating Projects

In the intricate planning and assessment stage of our skating projects at Sullivan Industrial Services, we leave no stone unturned. Our team dives deep, studying machinery specifics and scrutinizing the relocation landscape. This careful approach ensures a finely tuned skating project, custom-fit to meet your unique needs and overcome any challenges in the process.

Steps Involved in Machinery Skating

- Site Analysis: We explore your machinery and its new home, understanding every nook and cranny.

- Rigorous Planning: We put on our thinking caps, strategizing meticulously for a seamless skating spectacle.

- Strategic Positioning: We place low-friction skates with precision for that smooth glide.

- Skilled Execution: Our seasoned team moves your machinery with grace and expertise.

- Continuous Monitoring: We oversee and tweak in real-time for a smooth relocation.

- Final Assessment: Lastly, we ensure your machinery is in the correct place and secure.

Types of Machinery Suitable for Skating

CNC Machines:

Precision meets mobility as our machinery skating caters to the intricate movements of CNC machines, ensuring their seamless relocation.

Generac Generators:

Our skating approach ensures a graceful move for Generac generators—powerful yet deserving of a gentle touch.

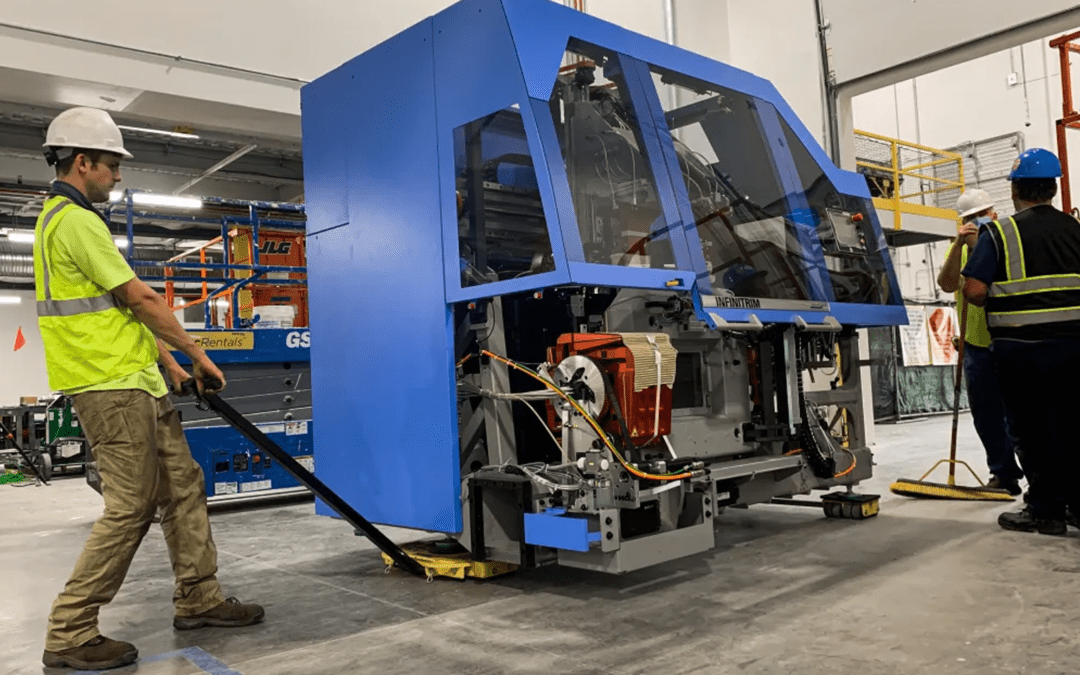

Printing Machines:

For the heartbeat of printing, our machinery skating guarantees a smooth relocation, treating these vital machines with the care they deserve.

Milling Machines:

Precision meets perfection as our machinery skating glides milling machines into their new workspace with finesse.

MRI Machines:

Handling delicate MRI machines, our expertise ensures their secure relocation, preserving the precision of their sensitive components.

Heavy Industrial Equipment:

Our versatile machinery skating embraces the weight and power of heavy industrial equipment, ensuring a robust and secure journey to their new destination.

Tools and Equipment Used in Machinery Skating

Overview of Skating Tools: Jacks, Skates, and More

Our arsenal of skating tools encompasses a variety of essentials like jacks and skates, vital for precision in machinery relocation. Hydraulic jacks, with their lifting prowess, form the backbone, elevating machinery for smooth movement. Low-friction skates play a crucial role, gliding heavy loads around effortlessly. These tools, combined with our expertise, create effortless efficiency, ensuring that each piece of machinery, regardless of size or weight, enjoys a graceful journey to its new destination.

Sullivan’s Newest Addition: The Solo 20 Revolution

Sullivan Industrial Services proudly introduces the Solo 20, our latest acquisition. This electric-powered dolly boasts a 20-ton capacity, revolutionizing our machinery skating capabilities. Lift loads effortlessly with toe jacks, slide the skates and robot underneath, and maneuver seamlessly in confined spaces. With the Solo 20’s compact design, wireless remote control, and custom lithium batteries, Sullivan guarantees precise and efficient machinery skating while prioritizing safety.

Risk Assessment and Safety Protocols

- Thorough Risk Assessment:We take a proactive approach in, foreseeing potential challenges and hazards.

- Tailored Safety Protocols: Before every job we address site specific risks for a safeskating process.

- Continuous Monitoring: We make real-time adjustments to ensure everything runs seamlessly.

- Experienced Team: Our skilled professionals execute each step with precision.

- Safety-first Approach: It’s not just a policy; it’s our commitment to infuse every skating move with an extra layer of safety.

Training and Expertise Required

At Sullivan Industrial Services, we take pride in our machinery skating abilities, and that starts with our exceptional team. We handpick skilled professionals with top-notch training, ensuring they bring expertise and precision to every move. Your machinery deserves nothing less than the best, and we deliver just that.

Case Studies: Successful Machinery Skating Projects

Examples of Skating in Different Industries

- Manufacturing Plants: Relocating heavy machinery for process optimization.

- Construction Sites: Precise movement of equipment for efficient project execution.

- Power Generation: Transporting large generators and turbines.

- Aerospace Industry: Delicate relocation of precision tools and machinery.

- Medical Facilities: Seamless movement of specialized medical equipment for facility upgrades and efficiency.

- Technology Sector: Handling intricate machinery with care during office relocations.

Lessons Learned and Best Practices

Each machinery skating project is a journey of refinement. With each challenge, we glean lessons, shaping our practices for precision. Meticulous planning, adaptable strategies, and an unwavering commitment to safety define our best practices, guaranteeing flawless execution in every relocation. It’s a commitment to constant improvement and excellence.

FAQs About Machinery Skating

How does machinery skating differ from traditional relocation methods?

Machinery skating involves low-friction skates and precise maneuvers, offering a more controlled and efficient approach compared to traditional relocation methods.

What types of machines are suitable for skating?

Our capabilities extend through a diverse range of machine types, from industrial giants to precision tools. We tailor our skating experience to accommodate the unique needs of each machinery type.

How do you ensure safety during the skating process?

We conduct thorough risk assessments, craft tailored safety protocols, and maintain continuous monitoring. Our experienced team executes each step with precision, prioritizing safety throughout the entire process.

Can machinery skating occur in confined spaces?

Absolutely. Our skilled team is adept at maneuvering machinery in confined spaces. We use specialized techniques and tools to navigate tight areas, ensuring a smooth and controlled relocation even in challenging environments.

Concluding Our Machine Skating Guide

As we wrap up, let’s highlight the essence of professional machinery skating—precision, efficiency, and tailored solutions. Sullivan Industrial Services is your committed partner for seamless relocations. If you’re ready to experience the smooth glide of your machinery, give us a call. Your journey to efficient machinery rigging and relocation begins with us.

Contact Information for Specific Queries

For specific queries or more information, reach out to us at contact@sullivanindustrialservices.com or give us a call at 203-859-4238. We’re here to provide tailored solutions for all your machinery skating and rigging needs.

Recent Comments