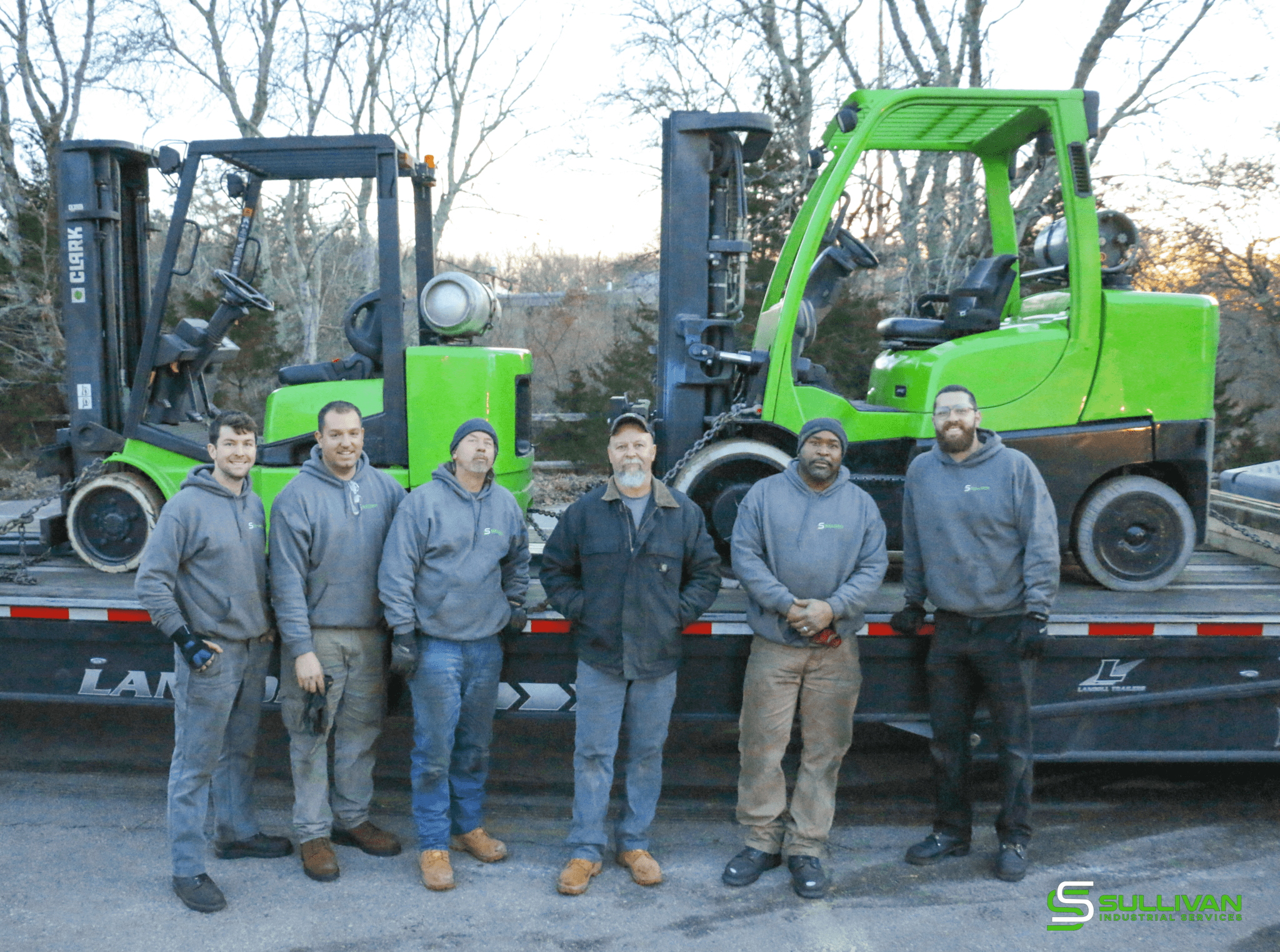

To put it simply, rigging is the process of lifting and relocating equipment. While this may sound like, rigging can be a complex process and it needs to be completed with careful accuracy. Rigging holds an importance across a variety of areas including the industrial, construction, and entertainment sectors. Sullivan Industrial Services recognizes this and as such, provides full-service rigging solutions for an array of clients in Connecticut, Massachusetts, Rhode Island, and New York.

Contact Sullivan Industrial Services for Any of Your Rigging Needs in CT, MA, RI, or NY

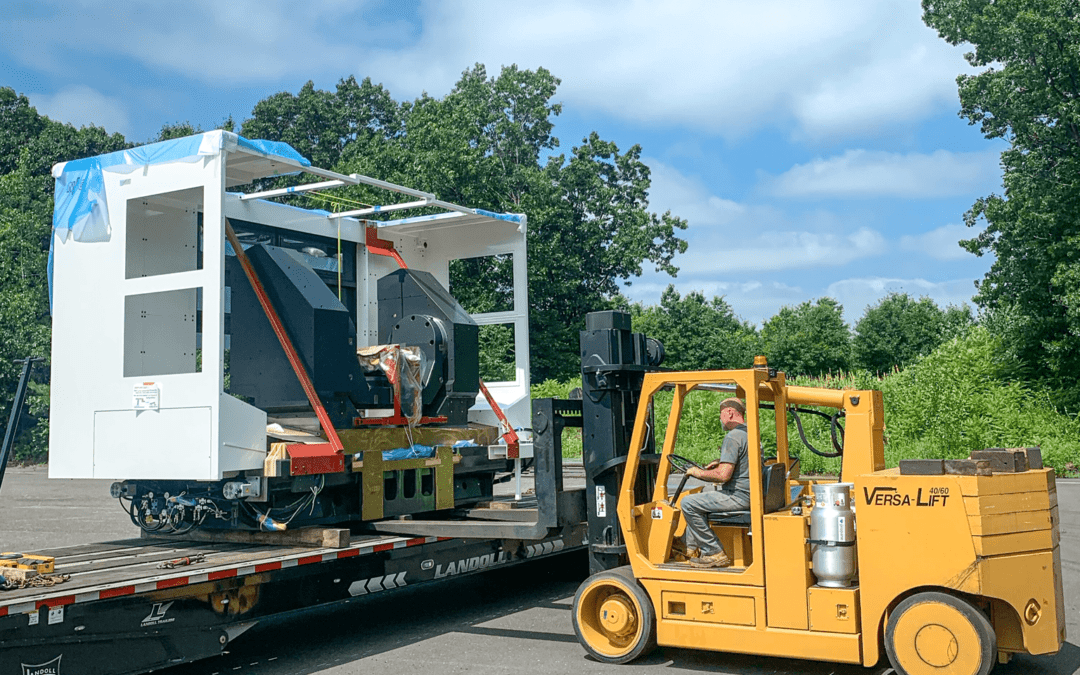

We bring more than five decades of combined industry experience to your rigging and machine-moving project. Our team has the necessary expertise to precisely maneuver, lift, and relocate your equipment and machinery. In this blog, we’ll discuss the machines and methods used in our rigging and machine moving process.

Machines Used in Modern Rigging

Rigging can be a laborious operation and as such requires specialized tools and machines to make sure the project is completed safely and efficiently. Here is a list of the machines that are often used in rigging:

Cranes:

These are used to lift or lower heavy loads and move them horizontally. All cranes are equipped with pulleys and cables. They are often used in construction sites, warehouses, and other settings.whether crating is the best option for you. If you are unsure about this, be sure to seek advice from the professionals.

Forklifts:

These vehicles are equipped with a forked platform on the front, and they can lift and transport heavy items over short distances.

Dollies & Skates:

These wheels are placed under heavy objects to facilitate their movement across flat surfaces.

Boom Lifts:

Also known as cherry pickers, these are used to lift workers and materials to certain heights, especially in construction or maintenance tasks.

Roll-A-Lifts:

Combining the function of jacks and skates, they can lift and then move certain machinery. Roll-A Lift’s are ideal for lifting and moving heavy objects such as safes, autoclaves, and freezers.

Gantry Systems:

These are frames used to support lifting devices, often in warehouses.

List of Methods Used in Modern Rigging

You can’t apply the one size fits all mentality to rigging. There are different methods of rigging to be used depending on the equipment that needs relocating. Here is a list of some common methods:

Jacking:

Jacks are used to elevate heavy equipment or machinery so that you can either work beneath them or place machinery-moving tools such as skates underneath.

Use of Skates / Rollers:

Skates are essentially industrial roller blades which allow large items to roll across the floor. Most large machinery do not have suitable wheels for moving the machine from one location to another. By placing skates underneath the machine, you can amend that situation and easily cart the object around.

Chain Fall & Gantry System:

You can lift and move heavy objects by using a chain fall mechanism suspended from a gantry.

Helium Bar Lifting:

A specialized method using leverage to lift an object when a traditional jack isn’t feasible.

Dead Hanging:

Used in the entertainment sector, this method involves hanging equipment in fixed positions, especially in stage setups.

Manual Operation:

This method relies more on physical strength as you use simple tools to adjust or move equipment.

Motorized Rigging:

Using motor-driven systems to facilitate the movement or lifting of heavy objects.

Use of Slings:

Wrapping heavy objects, such as blocks of concrete, in slings so that they can be safely lifted by cranes.

Safety Harnessing:

A safety harness is a system of restraints that prevent the wearer from falling from a height. So, this method ensures the safety of riggers working at heights.

Tandem Lifting:

Employing two or more cranes in unison to lift especially large or awkward loads.

Understanding the Basics of Rigging

As we previously touched on, rigging involves lifting and relocating various items such as equipment and heavy machinery. You could be moving items within a single space or even across multiple locations. No matter the type of project, this is an operation that involves the use of specialized tools such as shackles, slings, turnbuckles, wire rope, chains, jacks, etc. Riggers will examine an object’s size, weight, and balance point, then determine the best method to maneuver said object to its intended destination. Riggers decide what tools and equipment are needed to complete the job.

Historical Perspective

Rigging goes back thousands of years. In fact, it is believed Egyptians used rigging to build the pyramids, including the Great Pyramid of Giza which is the only one of the Seven Wonders to remain largely intact. The cutting, moving, and rigging of the large stones is still somewhat of a mystery but there are several prevailing theories. One of the most solid theories indicates the use of ramps and roller-track and pulley systems. Rigging consisting of a large lever and counterweight were attached to a cedar sled, much like a crane. The sand in front of the sled was wetted to support the heavy sled and help it slide from quarry to pyramid. A ramp was constructed to move the smaller stones into and through the pyramid. Like modern-day riggers, workers raised the larger blocks through the large gallery using a series of trollies, rollers, pulleys and counterweights. This ancient rigging system allowed a few dozen men to do the work of hundreds.

Safety Considerations in Rigging

Personal Protective Equipment (PPE)

Rigging can come with serious risks, so it is essential that riggers proceed with caution. Personal protective equipment (PPE) is necessary for any rigging project. Such equipment includes:

Protective clothing:

Every rigger should use protective clothing or coveralls that protect their body from welding sparks, chemical splashes, hot oil, water, etc.

Safety Shoes:

Grounds of many industries or construction sites are littered with cement, chemicals, or even sharp equipment that can cause injury to a rigger’s feet. Safety shoes must be slip resistant and provide a firm grip on the floor that enables the worker to perform all tasks safely.

Helmet:

Helmets or hard hats ensure safe covering for the head, protecting it from any falling objects.

Safety gloves:

Safety gloves should be heat resistant and made from cotton. They should be used for all general operations to protect the hands.

Safety Harness:

Rigging sometimes requires working on elevated heights. To avoid falls and ensure the safety of the rigger, a safety harness is used.

Safety Shoes:

Grounds of many industries or construction sites are littered with cement, chemicals, or even sharp equipment that can cause injury to a rigger’s feet. Safety shoes must be slip resistant and provide a firm grip on the floor that enables the worker to perform all tasks safely.

Safety Glasses/Goggles:

Eyes are one of the most important and sensitive parts of the body. They must be protected from exposure to harmful working conditions that can cause serious eye injuries.

Rigging Safety Standards

OSHA Guidelines

Safety should absolutely be the main priority for every rigging operation. To prevent injury or damage, the Occupational Safety and Health Administration (OSHA) regulates the safety of rigging equipment and operations. OSHA qualified riggers must possess a recognized degree/certificate or have extensive knowledge, training, and experience, and can successfully demonstrate the ability to solve problems related to rigging loads.

Reach Out for Your Rigging & Machine Moving Needs Today!

As you can understand by now, it is incredibly important that we use proper rigging practices. Failure to do so can result in harm done to the equipment or even injury to the rigger. It is essential that you use the correct machinery and tools while employing the appropriate method. Of course, safety should always be the number one priority. You want to be in line with all safety standards because not doing so can be detrimental. Here, at Sullivan Industrial Services, we understand that no rigging project should be taken lightly. We bring accuracy, expertise, and caution to every rigging project we’re called to complete. We value getting the job done correctly. So don’t hesitate to reach out to us to fulfill your rigging and machine moving needs!

Recent Comments