Contact Sullivan Industrial Services for Any of Your Rigging Needs in CT, MA, RI, or NY

You may be surprised to learn that rigging is a critical component across a variety of areas including the industrial, construction, and entertainment sectors. First, rigging industrial machinery is an essential moving phase and industrial riggers are used by numerous industries to ready their spaces for active work. Second, rigging is a key aspect in construction because without rigging systems, construction projects would not only be highly dangerous but impossible. And third, rigging has many ties to the entertainment industry in that it involves hanging accessories in the air to maximize the space available on the stage. Thus, as you can see, rigging is a prevalent and versatile process across industries.

Here, at Sullivan Industrial Services, we bring more than 15 decades of combined industry experience to your rigging and machine-moving project. We offer full-service solutions to key areas across Connecticut, Massachusetts, Rhode Island, and New York. Our team has the necessary expertise to precisely maneuver, lift, and relocate your equipment and machinery. In this guide, we will provide you with all the information you need to know about rigging. You will learn what types of rigging there are, what rigging services we provide, safety considerations, and the kinds of equipment and training necessary for rigging. By the end of this guide, you will have a more complete understanding of how rigging works.

Types of Rigging

Industrial Rigging

Machinery

Machine rigging utilizes special equipment to lift and transport heavy machinery from one location to another. With rigging services, an industry can repurpose their facilities or change locations entirely with ease.

Heavy Equipment

When it comes to rigging extremely heavy objects, cranes and pulley systems are needed. The rigging process can be made all the more complex because of the sheer size of the equipment being moved. Without careful attention and the correct expertise, heavy equipment can be incorrectly moved resulting in serious injury and costly damage.

Entertainment Rigging

Stage

Stage rigging refers to how equipment on stage is suspended and/or moved. The ability to move scenery pieces up and out of the way maximizes the space on a stage. There can be several types of rigging systems used in a single stage, depending on production and budget limitations. Rigging can be dead hung, manually operated, or motorized, and serves many purposes.

Lighting

A rigging system is necessary in creating an effective lighting design for any stage production. The rigging process ensures the quality and security of equipment, crew, and performers. Lighting fixtures need to be hung and focused according to your plot, and further secured with clamps, safety cables, and gels. The light fixtures, also, need to be connected to power sources and circuits. Throughout a performance, the rig should be monitored and controlled, and any issues immediately troubleshooted. After a performance, the rig needs to be properly dismantled and removed.

Construction Rigging

Steel

Steel is one of the heavier loads in the construction industry. Steel will most likely need to be hoisted and lowered using equipment such as forklifts, boom lifts, overhead cranes, etc. It’s highly important that riggers secure such a heavy load using the right tools so that it doesn’t fall off during the process.

Concrete

Much goes into the process of lifting and moving concrete. You have to select the proper rigging – ropes, chains, slings, and inserts – to have a successful lift. Improper lifting could result in concrete damage. Additionally, riggers must consider a concrete load’s size, weight, and center of gravity at the start of the rigging procedure. When it comes to concrete, slings are the most commonly used device for lifting. Slings are normally formed from chain, wire rope, fiber, or synthetic rope.

Regional Services

As we previously mentioned, we offer rigging services in key areas throughout Connecticut, Massachusetts, Rhode Island, and New York. From small in-house projects to large crane operations, we can do it all. Here are some examples of our past rigging projects:

CNC Machine:

-

- We move everything from DMG Mori DMU machines to USA-made Methods Machine Tools.

Delmar Electric Generac Generator:

-

- The Sullivan Industrial Services Team used a crane operator to ensure the safe placement of a Generac generator.

Printing Machine:

-

- We worked with clients like Amazon’s Printing Division & others to move Heidelburg Presses, as well as more modern manufacturers like Fujifilm.

Brewery Tanks:

-

- The Sullivan Industrial Services Crew rigged and installed brewing tanks for Counterweight Brewing Company and New England Brewing Co..

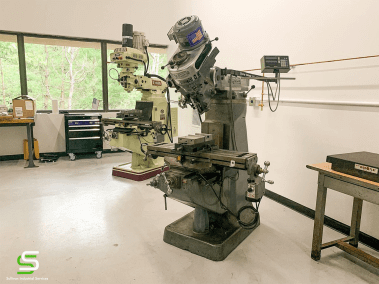

Milling Machines:

-

- Our time is always moving milling machines like Bridgeport Millers..

MRI Installation:

-

- Using a crane, we hoisted an MRI machine through the roof of a medical building.

Safety Considerations

Personal Protective Equipment (PPE)

Rigging can come with serious risks so it is essential that riggers proceed with caution. Personal protective equipment (PPE) is necessary for any rigging project. Such equipment includes:

Protective clothing:

-

- Every rigger should use protective clothing or coveralls that protect their body from welding sparks, chemical splashes, hot oil, water, etc.

Safety Shoes:

-

- Grounds of many industries or construction sites are littered with cement, chemicals, or even sharp equipment that can cause injury to a rigger’s feet. Safety shoes must be slip resistant, and provide a firm grip on the floor that enables the worker to perform all tasks safely.

Helmet:

-

- Helmets or hard hats ensure safe covering for the head, protecting it from any falling objects.

Safety gloves:

-

- Safety gloves should be heat resistant and made from cotton. They should be used for all general operations to protect the hands.

Safety Harness:

-

- Rigging sometimes requires working on elevated heights. To avoid falls and ensure the safety of the rigger, a safety harness is used.

Safety Glasses/Goggles:

-

- Eyes are one of the most important and sensitive parts of the body. They must be protected from exposure to harmful working conditions that can cause serious eye injuries.

Rigging Safety Standards

OSHA Guidelines

Safety should absolutely be the main priority for every rigging operation. To prevent injury or damage, the Occupational Safety and Health Administration (OSHA) regulates the safety of rigging equipment and operations. OSHA qualified riggers must possess a recognized degree/certificate or have extensive knowledge, training, and experience, and can successfully demonstrate the ability to solve problems related to rigging loads.

State-Specific Regulations

In the rigging industry, there are a variety of associations that set standards and specific requirements that may vary from state to state. Additionally, different types of jobs and rigging equipment may come with unique safety requirements. Still, there are a few standard organizations that have a major hand in setting statewide rigging requirements.

We’ve already mentioned OSHA which is perhaps the best known workplace safety organization. While each state may develop its own health and safety standards, they are still overseen by OSHA and OSHA does set some federal standards.

Moreover, the National Fire Protection Association (NFPA) is responsible for issuing standards related to fire protection and prevention, and the National Electric Code (NEC) specifically deals with electrical safety.

Finally, the American Society of Mechanical Engineers is a professional association that also helps set the standards and codes in the rigging industry. This association may require riggers to complete certain certification courses. Managers may also be required to complete Competent Person fall protection courses.

Common Risks and How to Avoid Them

Overloading

A frequent fault in rigging is ignoring weight limits. Every rigging component has a specific capacity that should not be exceeded. However, due to lack of knowledge or in time crunch situations, workers overlook this crucial aspect. Overloading a rigging system can lead to catastrophic failures such as structural damage and severe injuries. It is vital that riggers adhere to weight limits and receive adequate training to do so.

Improper Attachment

The way rigging components are connected significantly impacts the safety of lifting operations. Improper rigging attachment can lead to load instability, uneven weight distribution, and compromised structural integrity. Riggers should receive thorough training on various rigging techniques and be sure to follow industry standard rigging practices.

Environmental Factors

Before beginning any rigging project, riggers should create a Jobsite Hazard Analysis (JHA). The JHA addresses each hazard and comes up with a precautionary method in response. Potential hazards and risks rigging teams may face include: inclement weather, weak foundations, slopes / ramps, pedestrian and vehicular traffic, slips / trips, noise, dust, heat, and recently COVID-19.

It cannot be stressed enough how important it is for riggers to be knowledgeable of the space surrounding the lift area and the travel path of the equipment being moved. Ground barricades and posted signage around lifting equipment serve as fundamental visual communication for the crew and any other persons in the area to understand that risk is present.

Common Rigging Tools That Maximize Safety

There is a variety of rigging tools needed to work with machinery of substantial size and weight. By using these tools, you can handle such machinery with caution and accuracy. Generally, using the proper rigging tools can increase the safety and efficiency of the overall process. Common rigging tools include:

Jacks:

A simple jack can be used to move machinery and heavy objects to get the item elevated. There are a variety of jack types which can be applied in different situations. By using a jack for support, you lift the physical burden off yourself in lifting heavy machinery.

Skates:

Skates are essentially industrial roller blades which allow large items to roll across the floor. Most large machinery do not have suitable wheels for moving the machine from one location to another. By placing skates underneath the machine, you can amend that situation and easily cart the object around.

Roll-A-Lifts:

Roll-A Lift’s are ideal for lifting and moving heavy objects such as safes, autoclaves, and freezers. This tool combines the lifting power of a jack and the roller blading idea of skates together in one. However, Roll-a-Lifts can only be used on vertical flat surfaces such as the items listed above.

Gantry & Chain Fall:

A gantry is a supporting structure consisting of a horizontal support beam raised by two vertical stands. When equipped with a chain fall this combination of rigging equipment can be used to hoist objects in a variety of applications including out of holes or off their stands. Again, this tool combination saves you the trouble of lifting heavy machinery.

Helium Bar:

Sometimes a machine mover may encounter a situation where they need to elevate an object or heavy machine, but a jack cannot be used. A helium par provides leverage by using the body weight of the rigger compiled with the natural lever design of the helium bar. Once elevated basic wood blocks can be placed under the object and a jack can be inserted to continue the elevation process.

Rigging Equipment

Cables and Ropes

Material Types

The two primary types of rope used for rigging are manila rope and polyester rope. The natural strength and all around utility of manila rope has made it the standard for quality rope. Manila’s absorbing quality makes it the first choice for many physical activities that require direct handling of rope. Furthermore, polyester is considered to be the best general-purpose rope. It’s one of the most popular choices when a tough heavy-duty rope is needed. Polyester rope is a great rope for general industrial applications as well as rigging applications. This material is rot, UV and abrasion resistant, and retains strength when wet or dry.

Maintenance

Cables and ropes should be stored in a dry, cool, and well-ventilated area away from direct sunlight and other elements. Exposure to UV and moisture can weaken the rope fibers, leading to premature aging and damage. When using the ropes, it’s essential to avoid sharp angles and prevent kinks. Either of these can cause structural damage to the fibers and reduce the rope’s strength. When uncoiling a rope, you should use a roller to prevent twisting and kinking. Ropes should also be regularly lubricated to reduce friction between the fibers and using a high-quality lubricant can prolong the rope’s life. Finally, when it comes to cleaning cables and rope, use a mild soap and warm water solution, gently scrubbing the rope with a soft brush. Rinse the rope thoroughly with clean water and hang it to dry.

Hooks and Clamps

Selection Criteria

There are two main types of hooks used for rigging – overhead hooks and non-overhead hooks. Overhead hooks are mainly used for lifting equipment whereas non-overhead hooks are designed for pulling or load securement. Overhead hook types include:

Clevlok Hooks:

-

- This line of hooks offers easy installation and are 100% proof tested.

Eye Hooks:

-

- These hooks are designed for overhead lifting and can be used in place of Clevlok hooks.

S Hooks:

-

- “S” Hooks are built and designed for special lifting applications.

Plate Hooks:

-

- Plate Hooks are designed for lifting plate material in vertical and horizontal orientations. Plate hooks should be used in pairs and careful attention should be paid to sling angles when determining the working load limit.

Sorting Hooks:

-

- Sorting Hooks are designed to lift and move material with long narrow throat openings.

Non-overhead hooks include:

Clevis Hooks:

-

- Clevis Hooks are used for load securement with tie-down chains. Clevis hooks can be used in combination with various grades of chain. These hooks feature a U-shaped attachment point with a pin to secure chain or other rigging attachments. Different grades of clevis hooks have different working load limits; therefore you must ensure you use the correct hook grade and size for your application.

Eye Hooks (Non-Cradle Grab & Slip Hooks):

-

- Standard Eye Hooks can also be used in combination with various grades of. Eye hooks feature a simple circular attachment point for rigging chain or other attachments.

Inspection

Rigging hooks and clamps should be inspected thoroughly before each job. Depending on their condition, they may have to be discarded. For example, rigging hooks that are worn more than 10% of the original dimension or are worn beyond a specific dimension should be discarded. Hooks that have slot openings greater than ¼ inch should be discarded. Also, discard hooks with any apparent bend or twist. In addition, any replacement parts should be equal to the original manufacturer’s specifications and obtained from the manufacturer of the hook. All replacements and repairs should be performed by a qualified person.

Cranes and Hoists

Types of mobile Cranes include:

Crawler Cranes:

-

- Crawler cranes are the largest mobile cranes. These are heavy duty cranes that utilize “tank-like” treads to move throughout a construction site and can lift in excess of 2500 tons. Due to their extensive on-site assembly, massive size, and treads, crawler cranes are not road legal.

Rough Terrain Cranes:

-

- Known as “RT” cranes, these cranes are designed for “off-roading” in challenging environments such as mud and snow. Rough terrain cranes are mounted on four tires and use a telescoping boom for pick and carry operations up to 165 tons..

All-Terrain Cranes:

-

- An all-terrain crane can travel both on the road and on most off-road surfaces. A telescopic boom mounted onto the bed of the truck is used to lift and move loads. All terrain cranes can lift up to 1200 tons.

Truck Cranes:

-

- Truck cranes are made of a boom mounted to a truck bed and are, therefore, road legal. Truck cranes are smaller, less versatile, and used for lifting lighter loads.

Carry Deck Cranes:

-

- A carry deck crane consists of a rotating, telescopic boom mounted to a small, flat platform with four wheels. These cranes use outriggers and tend to lift loads at around 4-10 tons.

Moving on to hoists, there are three key features to look for when deciding on a hoist – power, loud chain, and mounting. Each of these features will impact the cost, effectiveness, and utility of the hoist. Regarding power, there are a few types – pneumatic, electric, and manual. The two most common materials hoists use to lift are load chains and wire ropes. You’ll have to decide which of those will suit your job best. And the last crucial aspect to pay attention to when purchasing a hoist is how that hoist is mounted. There are several mounting configurations of hoists.

Operational Guidelines

According to OSHA, cranes must be inspected by a qualified person at least once a year. Additionally, crane operators must be trained to inspect cranes before every use for additional safety. When operating a crane, all personnel must wear adequate personal protective equipment (PPE) at all times. Don’t forget, developing visual signals is key. When the crane operator has a limited view, a qualified person on the ground should be giving clear visual cues to direct operations. In these cases, the best way to overcome the blind spots is through crane camera systems and two-way radios for easy communication.

Rigging Techniques and Best Practices

Load Balancing

Load balancing is a must so as to prevent any shifting of the load’s contents. Half-full containers are especially tricky loads. To stabilize such a load, transfer the contents and move the container empty or fill it all the way up so it can be lifted as a solid volume with no shifting.

Knot Tying Techniques

Common Knots

There are several knot types commonly used in rigging procedures. Those knots include:

Square Knots:

-

- Square knots are composed of two overhand knots turned in opposite ways. It flattens when pulled tight, making it useful for tying loads.

Clove Hitches:

-

- The clove hitch is made by passing the rope’s end around an object and then crossing it over the rope’s standing part to form a loop, then passing the end around the object again to form a second loop, through which the end is passed.

Double Half Hitches:

-

- A double half hitch is formed by making a second half hitch around a rope’s standing part.

Sheet Bends:

-

- The sheet bend is made when the end of one rope is passed through a loop of the other, is passed around the loop, and under its own standing part.

Specialized Knots

There are two specialized knots you may incorporate into your rigging project. First, there is the Munters Hitch. This simple but effective knot allows riggers to lower heavy motors down from high surfaces such as catwalks. Second, the Alpine Butterfly knot is used to form a fixed loop in the middle of a rope. It can handle heavy loads in either direction of the knot.

Load Angles and Sling Tension

The sling angle is the angle where the sling meets the load. You need to measure that to find out how you properly choose the piece of rigging you need for the applied force that’s going to be on them. You want to check and make sure that the sling angle is correct for the lift. In the lifting and rigging industry, you want to make sure the angle is at least 30° or more. Lifting and rigging specialists tend to prefer 60° angles. 60° tends to be the baseline sling angle that riggers want to use and it applies to most sectors.

Equipment Inspection and Maintenance

Above all else, we want to avoid injury in the workplace. To do this, equipment must be inspected and properly maintained. Routinely checking the condition of your rigging, rope pulley blocks, and lifting hardware are essential. Rigging equipment inspection also detects and prevents equipment failure, which can help avoid damage and casualties. Additional advantages consist of an improvement in production and a decrease in the need for maintenance and repairs. Both the OSHA and ASME have released guidelines for rigging equipment inspection, removal of equipment, and inspection procedures for safety equipment harnesses and lanyards. Be sure to not only read up on them but practice them as well. When working with rigging, it is recommended that you check it daily. At the least, you should check it before every shift.

Training and Certification

Available Courses in CT, MA, RI, and NY

American Crane & Safety offers rigger training courses to those interested in Connecticut, Massachusetts, and Rhode Island. You can take either instructor-led video lessons or an in-person course, both offer the same course material.

The online NCCCO Certified Rigger 1 Preparation Course prepares you to take the NCCCO Certified Rigger Level 1 certification exam and practical testing. The CCO Rigger certification program is a nationally recognized and internationally accredited rigger certification program intended to certify the individual’s training, knowledge, skill base, and ability to perform functions related to the selection, inspection, and proper use of rigging equipment. To become an NCCCO Certified Rigger, candidates must pass both a written and practical examination. This course covers detailed reviews of rigging hardware and Lift Plans, practical videos, and review quizzes to prepare you to take the NCCCO Certified Rigger Level 1 certification exam and practical testing.

While American Crane & Safety doesn’t offer courses to residents in New York, you can still get your certification just as would in the other states. NY candidates must pass both a written and practical examination. Candidates have 12 months from when they pass either the written or the practical Exam to pass the corresponding exam for each rigger certification level.

Importance of Certification

To pass rigger certification exams and earn certification, comprehensive training is required to gain adequate technical knowledge and hands-on skills. Earning a certification is proof that an individual has the ability to perform their jobs more safely and efficiently.

How to Choose a Training Provider

When choosing a training provider, look for a program that provides a good combination of technical knowledge and hands-on examples to show application of the principles and techniques taught. A quality training program will have ample opportunities for hands-on instruction using pre-made scenarios that require the candidates to apply what they learned. In practicing these scenarios, you should be given proper feedback to ensure complete understanding of the concepts and techniques learned. Finally, a training program should include a pre-certification written exam so the candidate and the trainer can assess comprehension.

Future Trends and Technologies in Rigging

Automation and Robotics

The integration of automation and robotics in rigging operations will streamline processes, improve efficiency, and reduce human error. Autonomous cranes and robotic systems will be capable of performing complex lifting tasks with precision and accuracy. These advancements will not only increase productivity but also create a safer working environment by minimizing the need for human intervention in hazardous situations.

Sustainability in Rigging

Sustainability can be practiced in the rigging industry by shortening supply chains with local manufacturing. Short distances minimize carbon emissions from multiple transportation steps.

Virtual and Augmented Reality in Training

Augmented Reality (AR) and Virtual Reality (VR) technologies will transform rigging training and maintenance procedures. Trainees can undergo immersive virtual training experiences that simulate real-life scenarios, allowing them to practice their skills and enhance their knowledge in a safe and controlled environment. Additionally, technicians can use AR tools to access real-time information and instructions, improving equipment maintenance and troubleshooting processes.

Hire the Right Rigging Company

In this guide, we have given you a thorough and in-depth look into rigging practices. We’ve touched on types of rigging, rigging equipment, rigging techniques, workplace safety, and training. The information we’ve discussed is not just for your knowledge, but in sharing this guide, we hope to encourage proper rigging practices. Rigging is incredibly important across industries and must be done with care. That’s a firm belief we hold here at Sullivan Industrial Services. We take our rigging seriously and we ensure that we engage in proper rigging operations. If you have any questions or would like to inquire about our rigging services in CT, MA, RI, and NY, please don’t hesitate to reach out for a quote!

Rigging Services Near Me in Connecticut

When you hire Sullivan Industrial Services for your rigging project, you can expect you are hiring the best rigging team in the area. Our consistent focus on safety and efficiency is always at the forefront of each and every industrial rigging project. You can trust that the Sullivan Industrial Services team will ensure a safe and secure relocation of your valuable industrial machinery. From small forklift picks to large crane projects our team has the equipment to get the job done.

Sullivan Industrial Services is warehoused in Milford, CT with a second location in Bloomfield, CT, and serves small and large businesses throughout Connecticut including but not limited to:

- Shelton

- Stamford

- Bridgeport

- Bethany

- Danbury

- Norwalk

- New Haven

- East Haven

- Trumbull

- Greenwich

- New Fairfield

- Newtown

- Bethel

- Hamden

- Waterbury

- Meriden

- Naugatuck

- Woodbridge

- Hartford

- New London

- New Britain

These are just some of the towns that Sullivan Industrial Services offers our assistance in, so don’t worry if you don’t see your town listed here. Our services extend throughout all of Connecticut.

Resources and Additional Reading

Stage Rigging Handbook by Jay O. Glerum

Entertainment Rigging for the 21st Century by Bill Sapsis

Arena rigging: A Practical Guide for Riggers, Designers, and Managers by Harry Donovan

Entertainment Rigging by Harry Donovan

Rigging Math Made Simple by Delbert L. Hall

Recent Comments