Introduction

Relocating a commercial boiler is a complex process requiring careful planning, precision, and expertise. Whether upgrading to a new location, reconfiguring your existing facility, or replacing an outdated system, proper handling is crucial to ensure safety, efficiency, and compliance with regulations. Sullivan Industrial Services specializes in heavy equipment moving, including commercial boilers, providing a seamless transition from start to finish.

Do you Have a Commercial Boiler That Need to be Moved? Contact Sullivan Industrial Services to get Started!

Key Considerations for Moving a Commercial Boiler

1. Planning the Move

Proper planning is essential to prevent costly delays and safety hazards. Before beginning the relocation, consider the following:

- Site Evaluation: Assess the current and new locations to determine accessibility, space constraints, and any necessary structural modifications.

- Logistics Coordination: Establish a timeline, budget, and transportation route that accounts for road conditions, permits, and regulatory requirements.

- Downtime Management: Plan the move to minimize operational disruptions and coordinate with facility managers to ensure continued productivity.

- Vendor Coordination: Work with utility providers and relevant contractors to streamline the reconnection process at the new location.

2. Safety Precautions

Boilers are heavy and often contain hazardous materials, making safety a top priority. Important precautions include:

- Shutdown Procedures: Ensure the boiler is properly shut down, depressurized, and disconnected from gas, water, and electrical systems.

- Hazardous Material Handling: Drain and dispose of any remaining fuel or chemicals in compliance with environmental regulations.

- Personnel Protection: Ensure all workers involved in the move are equipped with appropriate personal protective equipment (PPE) and trained on safety protocols.

Emergency Preparedness: Have contingency plans for unforeseen issues, such as leaks or mechanical failures.

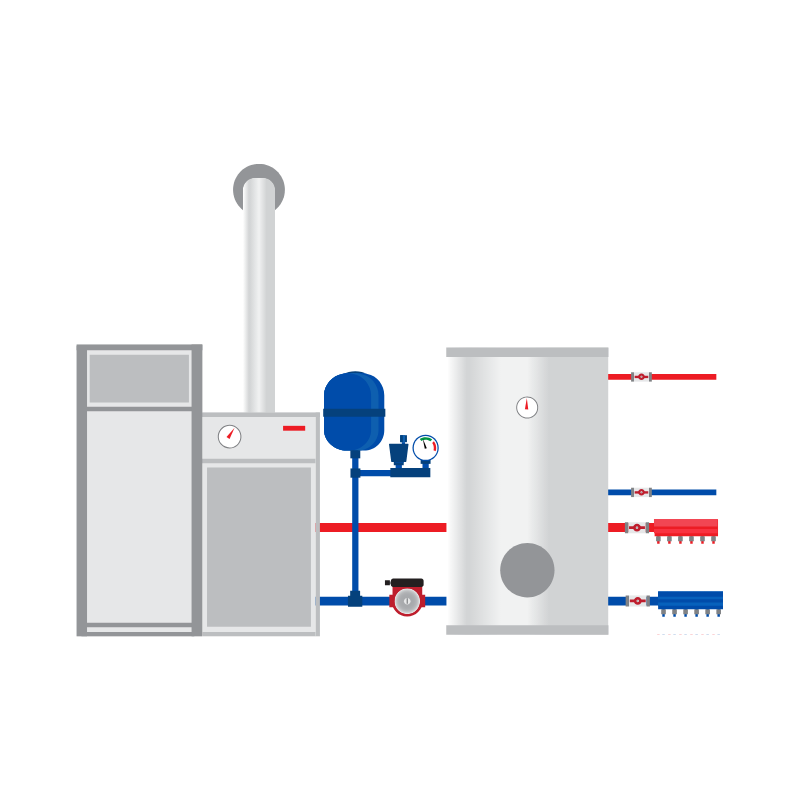

Steps to Relocating a Commercial Boiler

1. Equipment Disassembly & Preparation

Disassembly may be required to facilitate transport depending on the boiler’s size and design. This may include:

- Removing insulation, piping, and connections

- Disassembling significant components, such as burners and control panels

- Properly labeling parts for easier reassembly

- Conducting a thorough inspection to identify any wear and tear before reinstallation

2. Rigging & Lifting

Specialized rigging and lifting techniques are necessary to move a boiler safely. Sullivan Industrial Services uses advanced equipment, including:

- Cranes & Hoists: To lift the boiler and maneuver it within confined spaces

- Heavy-Duty Dollies & Rollers: For safe ground transport within a facility

- Custom Rigging Solutions: Tailored to the specific weight, dimensions, and structural considerations of the boiler

- Load Testing: Ensuring that rigging equipment can handle the weight before the move begins

3. Transport & Permits

Transporting a commercial boiler requires the following:

- Proper Permits & Clearances: Securing oversize load permits and coordinating with local authorities

- Secure Fastening: Using reinforced strapping and protective padding to prevent damage during transit

- Escort Vehicles (if needed): For oversized or wide-load transport

- Route Planning: Identifying the safest and most efficient path, avoiding potential hazards such as low bridges or weight-restricted roads

4. Installation at the New Location

Upon arrival at the new site, careful installation is necessary to restore full functionality:

- Positioning & Anchoring: Aligning the boiler in its designated spot and securing it to structural supports

- Reconnecting Utilities: Reintegrating gas, water, and electrical connections according to manufacturer guidelines

- Testing & Inspection: Conducting pressure tests, safety checks, and regulatory inspections to ensure compliance

- Calibration & Optimization: Fine-tuning the system to achieve maximum efficiency post-installation

CTPost: Sullivan Industrial Services Celebrates five years of seamlessly moving connecticut industry

How Sullivan Industrial started and succeeded in moving Connecticut industry

Common Challenges & How to Overcome Them

1. Space Constraints

Many boiler rooms have tight access points and limited maneuverability. The solution:

- Use modular disassembly to transport components separately

- Utilize compact rigging equipment for precise positioning

- Pre-measure doorways, hallways, and entry points to ensure smooth navigation

2. Compliance & Regulations

Regulatory compliance is crucial to avoid penalties and operational issues. Sullivan Industrial Services ensures:

- Adherence to OSHA and EPA guidelines for workplace and environmental safety

- Proper handling and disposal of hazardous materials

- Compliance with state and local transportation laws

- Documentation of all required safety measures to provide to inspectors

3. Boiler Damage During Transit

Unsecured or improperly handled boilers can sustain damage, leading to costly repairs. To mitigate this risk:

- Employ professional rigging techniques and protective measures

- Perform pre-move inspections to identify potential weak points

- Conduct post-move evaluations to confirm structural integrity

Why Choose Sullivan Industrial Services

With extensive experience in heavy equipment moving, Sullivan Industrial Services provides:

- Expertise in Boiler Relocation: Handling all aspects, from disassembly to reinstallation

- Specialized Equipment & Techniques: Ensuring safe and efficient transport

- Regulatory Compliance Assurance: Managing permits, environmental considerations, and safety protocols

- Minimal Downtime Strategies: Helping businesses resume operations quickly

- Turnkey Solutions: Offering full-service support, from planning to final testing

Moving Machines & Equipment Across CT & the North East

Sullivan Industrial Services is warehoused in Milford, CT with a second location in Bloomfield, CT, and serves small and large businesses throughout Connecticut and the North East including but not limited to:

Conclusion

Moving a commercial boiler requires expertise, careful planning, and adherence to safety and regulatory guidelines. Sullivan Industrial Services ensures a smooth, efficient, and compliant relocation process. Whether your move is across town or the country, our team has the skills and equipment to get the job done correctly. Contact us today to learn how we can assist with your next commercial boiler move.

Recent Comments